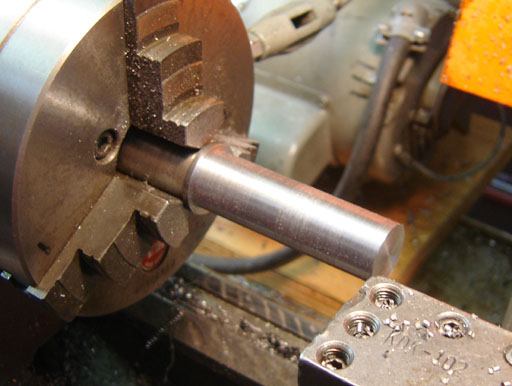

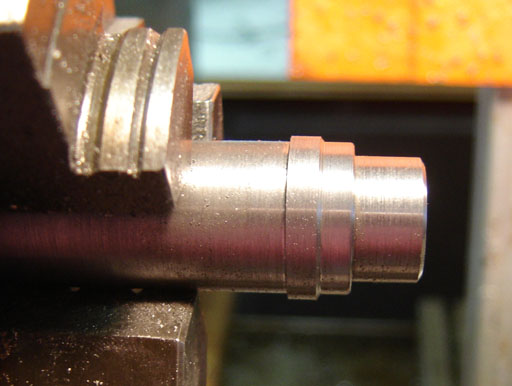

Drilling a hole the OD of the tube.

Deburring.

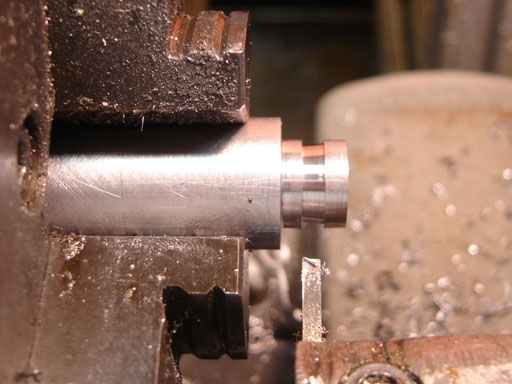

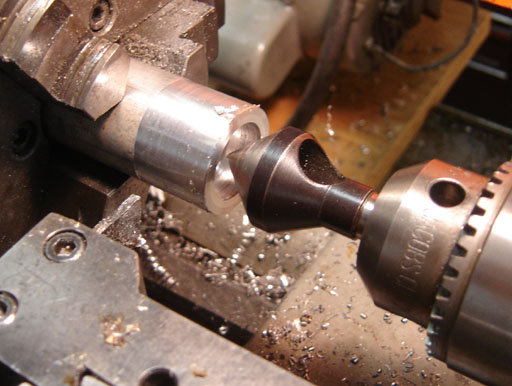

Parting off.

Flip and debur.

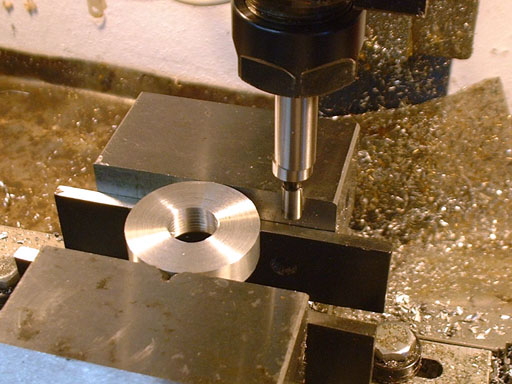

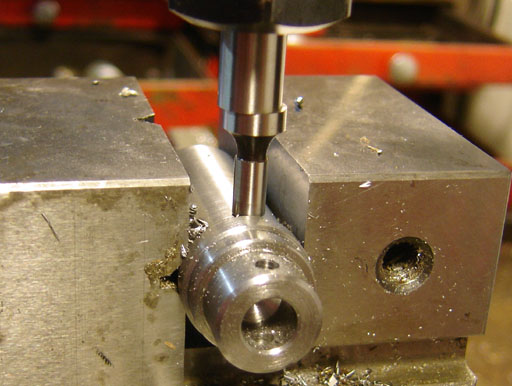

I didn't even put in a picture of an edge finder...drilling a #8 clearance hole.

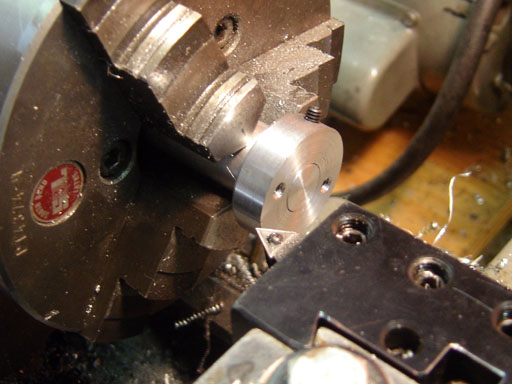

Making a flat spot.

Milling one side.

Milling the other.

Sawing one side.

And the part comes free.

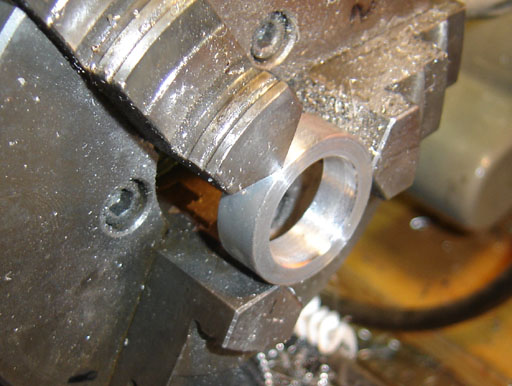

The clamping shoe. Those two screws are #8 button heads turned down to be a sliding fit in the slot.

The project is 75% completed. I now have a sliding stock, lockable and adjustable for length. Just the butt remains...