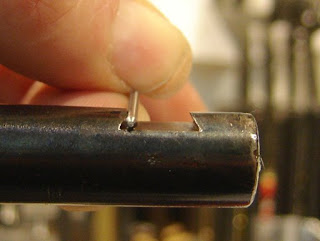

A caliper and a set of PeeDee thread wires.

I chose a wire size that was just below the top of the slot.

With wires in either side of the dovetail I measured the width, I got .217"

But when I verified this measurement with a gage block stack it would not fit. Calipers aren't that accurate.

So I tried .216" and it was spot on.

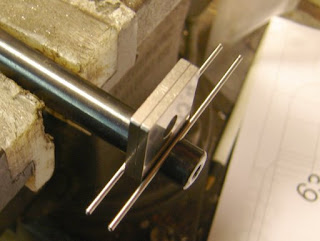

A side view.

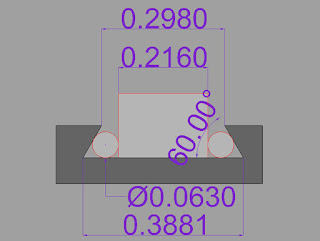

Here's a drawing.

The value we want is the width of the bottom of the slot.

We know the diameter of the pins, and the thickness of the gage block stack.

I assumed the dovetail was 60 degrees. It seemed to be.

So, knowing those and looking up the formula for measuring dovetails in Machinery's Handbook:

y=b–D(1 + cot 1⁄2α)

y=.2160

D=.063

α=60

b= base length

Since we need to know b, it becomes:

b=y+D(1 + cot 1⁄2α)

"cot" is a fancy way of saying 1/tan

tan 30 = 0.57735026918962576450914878050196

cot 30 = 1.7320508075688772935274463415059

+1=2.7320508075688772935274463415059

*D=0.17211920087683926949222911951487

+y=0.38811920087683926949222911951487

So that's how I got a value of .3881"

Honestly, I just wanted an excuse to do a little math tonight.