Rather than just remove the end plug I mounted it in the spring compressor.

There was nothing in that threaded hole, and I'm not sure why it's there.

I used a spacer so the force of the compressor would bear on the plug and not the safety.

Using an allen key in that threaded hole to unscrew the plug. I would unscrew a turn, back off the compressor, rinse and repeat.

It came out about this far once unthreaded.

The sear hangs down and is held by that pin.

The spring and guide. There was no spacer as shown in the webpage I linked to in part 1.

The piston.

The seal has definitely seen better days.

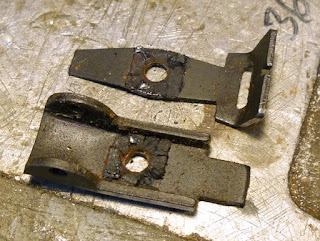

The sear removed.

A coil spring retains the safety.

I slid it off and pulled out that pin with pliers.

Then pulled out the safety. The other 630 is missing the safety and I'm not sure whether or not the rifle will work without it. I'd rather not make a duplicate of that.

I pried the seal off the piston. Finding replacement seals is tough. An email to CZ in the Czech Republic was unanswered. I found a Canadian airgun store that does sell replacement seals but they don't ship to the U.S. I have to convince my sister in Toronto to order some for her nut of a brother. But I'll probably have to make at least one seal in the interim.

The breech seal was also in poor shape. But it's just an o-ring.

I unscrewed the sight elevation set screw.

And punched out the pin.

A neat design. The leaf tensions the sight but pivots left and right for windage. Minimalist. Not sure what the rubbery stuff is - rubber probably. No front sights were on the rifles.

So that's it all apart. Not sure when I'll work up the enthusiasm for making a replacement seal...