I picked this Benjamin 3030 CO2 BB “rifle” (since it isn’t rifled) up on Gunbroker. I was always intrigued by the design and the advertised ability to “drive steel bb's clear through both sides of a 5 gal. steel pail at close range”. Why I’d want to do that isn’t the issue.

The rifle, rusty and dirty.

The wood looks like it could use a refinish.

The metal is pitted so I’m not sure what I’ll do. Probably paint it.

It cocks similarly to the Crosman 700/707 which it seems to share a similar mechanism with.

That’s the end of the 8 gram CO2 bulb sitting inside the cap.

Remove the stock screw.

Simple trigger.

An old rusty CO2 cartridge.

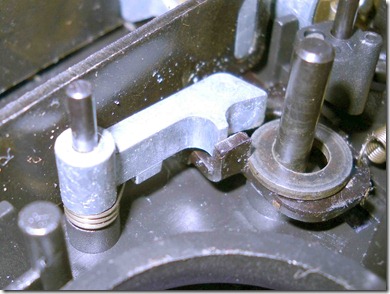

The cartridge seals here below the neck.

All that debris makes for a gritty trigger.

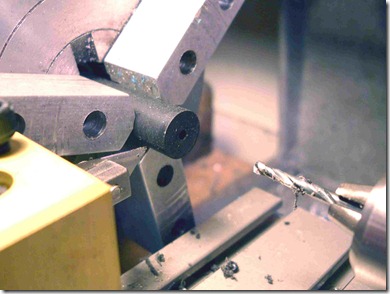

Two pins retain the trigger and spring.

Rear sight.

Removed.

More to come...