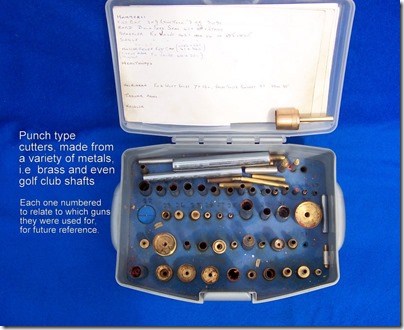

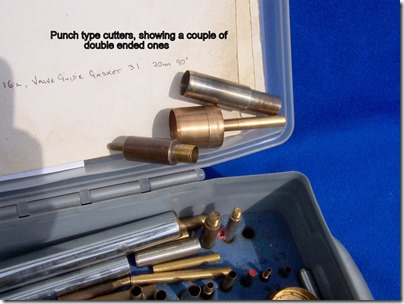

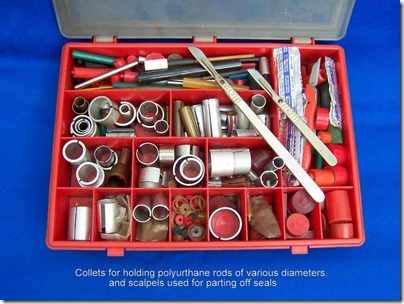

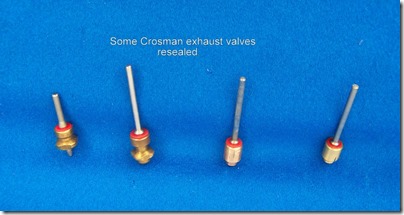

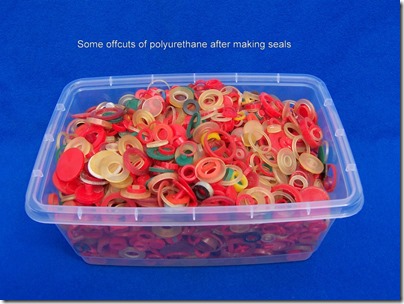

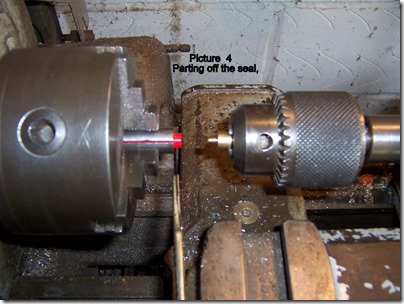

“I don't know if you have heard of me, my name is Lawrie Amatruda, I am in England UK, I read your great Blogs a lot, I hope you don't mind if I share with you my simple way of making flat section polyurethane seals, I am not an engineer, I'm getting to an age where I would like to pass on any helpful knowledge that I have to aid other DIY airgun enthusiasts to resurrect their old guns , I worked out this method some years ago after not very successfully trying to machine them on my lathe, I do lots of resealing of vintage and antique Co2 and pneumatic airguns for guys here, I hope the pictures are self explanatory.”

“…I believe that obviously from all the information you are giving the collectors around the world the knowledge to restore these older airguns for the next generation, the chance to do the same to their treasured collectables, after all we are only looking after them for future collectors to enjoy. Thank you for referring others to me here in the UK, although I am slowing down a bit now, because of my age, so I am fairly selective with the work I take on, mostly the vintage and antique Co2 and pneumatic airguns”.

Thanks so much for this hard-won knowledge Lawrie!