The washer was folded over the end of the piston (a clue for the observant).

A bit fuzzy on the end.

As you can see the washers are chewed up a bit.

I used a telescoping gage to determine the ID, I can't be sure the scrap of paper in front of me relates to this, but I think I wrote it down as .744" Don't quote me on that...

First I made a delrin seal and it wouldn't push the pellet out of the barrel, likely I made it a bit too small. So I turned some teflon...

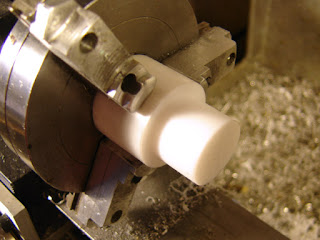

Making the counterbore for the screw.

Making a parachute lip. I have a lot to learn about this topic...

The teflon seal.

I installed it in the pistol and got speeds of about 160 fps. Adding a washer between the spring and guide for preload, I bumped it up into the 180 fps range. Not good. Notice that my lovely parachute seal failed to deploy, instead rolling inwards...the streaks on the side are either gasses or oil leaking past the seal...all in all, total failure.

So I pulled off the teflon seal. I then realized that the face of the piston should be a full circle, and that the thin flange was broken off at the sear.

So I made a washer for the face, .050" thick. I reinstalled the old, ugly and deformed (why didn't I notice that before?) leather seal. With the other washer in place under the spring to bump the spring preload up a bit, it now chronied at 348 (CPL's 7.9 grain), which is right about what the pistol is supposed to do. I will be making a new leather seal at some point in the future but for now the gun shoots fine.

Anyway, this all tells me I have a lot to learn about spring piston airguns...

1 comment:

awosome blog! keep up the good work.

Post a Comment