I love my

Crosman 167, but I absolutely hate the cheap stamped rear sight. Recently I bought a lot of random

Williams rear sights on

Ebay, for about $5.00 a piece. So I set about adapting one to the

Crosman.

The Williams sight and existing sight.

Windage is adjusted by loosening one screw and pushing the sight over.

Elevation adjustment is achieved by pushing in or out the notched ramp.

The Williams sight, while not a micrometer sight, has clearly marked index scales and is much easier to adjust.

Mounted in one screw hole, you can see that the other hole is not in the right place. I could tap the barrel, but I prefer to keep it in stock form (or easily

reversible).

The sight base has too large a radius.

A piece of aluminum was turned to the radius of

the sight base (I got it close and then checked until it seemed to have full contact.) Then it was offset eccentrically in the chuck.

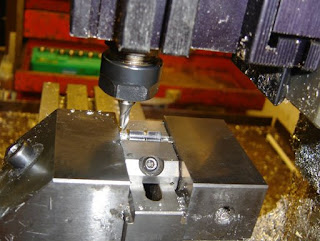

Drilling begins.

Drilled out to 1/2"

Then to 9/16". The

Taig isn't ideal for drilling with larger drills, but in aluminum it works fine.

Parted off.

With a plug inserted, and held in a

vee block, the eccentric piece is adjusted.

Sawing off my shim...

The shim fits perfectly.

The underside.

Marking one screw hole.

More to come...