As I mentioned in

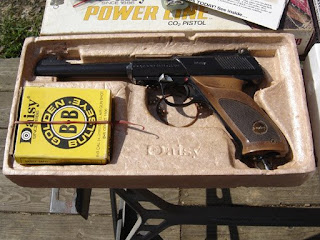

my earlier post on the old Diana Modell 5 I bought at the pawn shop, the deal included a

Crosman Phantom with a broken front sight. I finally ordered in a new front sight from Crosman. They do not have a manual or exploded drawing of the Phantom up, which is odd, and when I asked on the phone they said they did not have any replacement sights, but they did for the Quest.

The Quest is essentially the same rifle with a wood stock. So I ordered the Quest front sight. The sight doesn't look like the one in the Quest exploded drawing or pictures, so I'm unsure what exactly I ended up getting, but it looks like the broken Phantom sight. Perhaps Crosman customer service was able to find one. The cost was $2.20 (plus $4.00 shipping, but I ordered a fair amount of other stuff, including two 24" barrels for my projects at the same time) and the part# is C1K77-001

Derrick sent me a used Weirauch sight set but it seemed akin putting lipstick on a pig to use it on the Phantom, especially as I'll probably end up selling or trading it.

The broken sight.

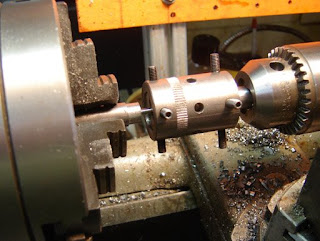

Tapping it off with a piece of wood and a hammer. It came off with blows of moderate force.

The barrel end. The straight knurl bites into the plastic, I didn't see any glue or epoxy.

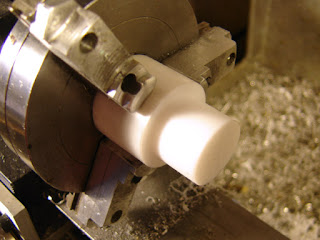

The crown seemed rough so I innocently thought I'd just give it a quick lap.

I pulled out my drawer of miscellaneous machine screws. I always keep a baking pan by my screws so I can dump out a drawer and search for what I need. I selected a small brass machine screw to use as a lap. No pictures because my camera decided to get drunk and all the pictures of the drill with the screw in it were blurry.

Might as well show this drawer unit full of screws, nuts, washers and bolts.

Oh and all my other tiny drawers of fasteners...there are even more in other places.

Anyway, I then pushed a

cleaning pellet into the barrel past the crown.

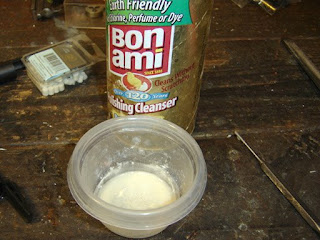

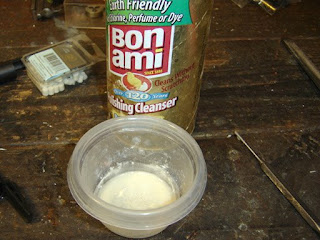

I thought I could use some Bon Ami mixed in oil...

But that didn't even barely remove any material, so I went with 1200 grit lapping compound.

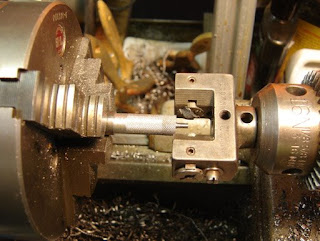

As you can see the crown was really rough, even with the 1200 grit it only hit the high spots. At this point I decided to cut my losses...so I chucked up a fine cratex pointed abrasive and went to work.

Which still didn't achieve much. So I had to decide between stripping the gun, removing the barrel, chucking it in the lathe, making a crowning cutter, recrowning, lapping again, and reassembling...or...just calling it good enough on a gun I don't care much for. So I called it good after relapping with the 1200 grit. I only needed to get it lapped right at the rifling transition to the bore, which I seem to have achieved.

I then tapped the new sight on just up to the knurling.

I looked down the barrel and made sure it was on straight. Then I hammered it home with a block of wood against the face. Notice the circular reflection of the light, I couldn't photograph it but I saw a similar reflection of the front sight's green dot, which aided in getting it all lined up.

I remounted the rear sight and shot a few pellets, seems to work fine.

This highlights my need to make a shooting bench so I can properly benchrest and sight in these projects...