The valve reassembled.

When screwing down the valve nut you have to make sure the port aligns. There's a hole opposite that lines up in this hole. What goes in the hole, if anything? I don't know.

I used a dowel pin to hold the valve, but removed it when the valve was tight. It shouldn't slip out of alignment?

A dowel pin is inserted through the tube into a hole in the bolt for cocking the hammer. It wasn't that hard to get it in using pliers.

The hammer, spring, spring guide and end cap were stuffed in. The hammer has a keyway that the dowel pin in the bolt rides in. Three screws hold the cap on.

Hammer and spring.

I reassembled it and tested to see if it worked. It did.

You can see how I used a hex nut to hold the action on the stock.

This is the bolt open. Notice the missing sight elevation screw.

The bolt closed, the bolt knob has a pin that enters a cam in the end cap to lock the bolt.

I stripped the rifle again and painted the action and barrel.

Drilling #3 for the knurled nut to hold the action on the stock.

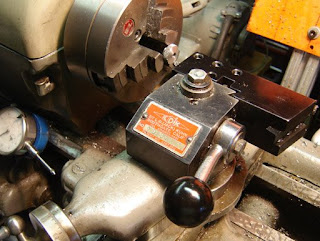

Tapping 1/4"-28. As always, I used the Fisher Micro Tap Guide.

Knurling. I should have put in a set of finer knurls...and those of you who know knurling, know it double tracked....but whatever, it's fine.

Turning the boss.

Turning the angle on the knob.

Blued and oiled.

All done!

Trust me, it wouldn't stand up to close scrutiny, and the wood is terrible. Not going to waste time refinishing, there are some deep stains and such. Besides it has character...

With Crosman .22 Premiers:

8 pumps, 630 fps w/ 14.3 gr. 12.6 ft/lbs

5 pumps, 535 fps w/14.3 gr. 9 ft/lb

3 pumps, 430 fps w/14.3 gr. 5.8 ft/lb

It's fun to shoot, and accurate!