Sidetracked from the 118 magazine when a buddy asked me to fix a leaky Crosman 454 semi-automatic BB pistol. This is a second variant due to the loop on the CO2 piercing screw at the bottom of the grip--which means it was made right around 1980. The gun uses a 12 gram CO2 cartridge housed in the grip and it holds 16 BBs. The BBs are held linearly above the barrel. A spring loaded plunger pushes the BBs backward to the breech where one is loaded with each trigger pull. The trigger is essentially double-action only with a pull that ranges from about 5-1/2 to 6 pounds of weight.

He told me the CO2 was leaking from the end seal.

The right side grip is clipped to the 12g CO2 cartridge and pulls right off. The left grip is held by two screws.

Yep, he was right. The end seal is almost non-existent.

Removed the rear sight.

Four screws hold the frame together.

Screws removed, the right-side half lifts off.

If you want to remove the barrel, there's a small screw on the underside just behind the muzzle. It retains the front sight--which in turn holds and centers the muzzle.

Of course, the safety ball bearing fired across the room when I lifted that right half. Some things never change. I scrounged a tiny replacement 3/32" ball bearing. (Nick probably still sells

bags of tiny bearings for just such occasions.)

Detached the hammer and trigger springs.

Small set screw retains the barrel in the valve. It's a 3/32". Just unscrewed it a turn.

Removed the valve anchor bolt in the left side of the frame.

Pulled the trigger pivot pin, wiggled the valve around then lifted off the hammer. The entire trigger, linkage and hammer assembly comes out as one piece. It's straightforward.

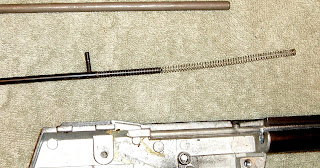

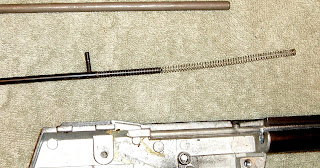

Slid out the smooth bore barrel. If you look at the breech end of the barrel carefully, there's a circlip in a groove that acts as a locater stop against the valve.

The BB follower is plastic. Look at that spring! That's exactly what I need for my Crosman 118 magazine. Think he'd even notice if the gun was only gravity fed?

Some valve pics. Rear. The silver protrusion is the valve stem that gets struck by the hammer.

Top. The screw holds a spring that pivots the BB shuttle (for lack of a better term).

Screw and spring removed. The shuttle slides right out. It picks up a BB from above and as the trigger is pulled, a transfer bar pivots the shuttle into alignment with the breech. It's a really simple, elegant design. Note: There are no seals on the side of the shuttle-- just an interference fit in the valve body.

Removed the cap from the front of the valve.

Valve spring and stem pulled out.

Ah, here's that bad cartridge seal. Unscrewed the threaded retaining ring.

Used a dental pick to work the crumbling seal out.

Underneath is a standard 38T/C piercing pin and screen filter.

Here's what the crumbled pile used to look like. Crosman's part # for the seal is 38-128. It's still available and used today in the Crosman 357 pistol.

Reassembled: Screen, piercing pin, seal, retaining ring.

Replaced the cap o-ring with one that looked similar in nitrile. Didn't replace the stem seal. It actually looked pretty good and it operates with 900 psi on it--that really helps keep it closed.

Greased the shuttle's sides to help pivot smoothly and seal.

A couple views.

Oh, I lubed the valve stem seal with a little

Crosman Pellgun Oil. The rest of the reassembly was pretty uneventful. I did refinish four or five of the visible screw heads, removing old screwdriver marks and rebluing. The gun gassed right up and fired 60+ shots without any hiccups. I'll give it back to him and he can finish giving it a shake down.

If I ever find one of these (and for the right price) it would be relatively easy to turn down 8" of 1760 barrel and shoot this with 0.177 cal lead balls. I'd imagine that the accuracy might even be pretty decent but probably not the velocity.

He told me the CO2 was leaking from the end seal.

He told me the CO2 was leaking from the end seal.

The right side grip is clipped to the 12g CO2 cartridge and pulls right off. The left grip is held by two screws.

The right side grip is clipped to the 12g CO2 cartridge and pulls right off. The left grip is held by two screws.

Yep, he was right. The end seal is almost non-existent.

Yep, he was right. The end seal is almost non-existent.

Removed the rear sight.

Removed the rear sight.

Four screws hold the frame together.

Four screws hold the frame together.

Screws removed, the right-side half lifts off.

Screws removed, the right-side half lifts off.

If you want to remove the barrel, there's a small screw on the underside just behind the muzzle. It retains the front sight--which in turn holds and centers the muzzle.

If you want to remove the barrel, there's a small screw on the underside just behind the muzzle. It retains the front sight--which in turn holds and centers the muzzle.

Of course, the safety ball bearing fired across the room when I lifted that right half. Some things never change. I scrounged a tiny replacement 3/32" ball bearing. (Nick probably still sells bags of tiny bearings for just such occasions.)

Of course, the safety ball bearing fired across the room when I lifted that right half. Some things never change. I scrounged a tiny replacement 3/32" ball bearing. (Nick probably still sells bags of tiny bearings for just such occasions.)

Detached the hammer and trigger springs.

Detached the hammer and trigger springs.

Small set screw retains the barrel in the valve. It's a 3/32". Just unscrewed it a turn.

Small set screw retains the barrel in the valve. It's a 3/32". Just unscrewed it a turn.

Removed the valve anchor bolt in the left side of the frame.

Removed the valve anchor bolt in the left side of the frame.

Pulled the trigger pivot pin, wiggled the valve around then lifted off the hammer. The entire trigger, linkage and hammer assembly comes out as one piece. It's straightforward.

Pulled the trigger pivot pin, wiggled the valve around then lifted off the hammer. The entire trigger, linkage and hammer assembly comes out as one piece. It's straightforward.

Slid out the smooth bore barrel. If you look at the breech end of the barrel carefully, there's a circlip in a groove that acts as a locater stop against the valve.

Slid out the smooth bore barrel. If you look at the breech end of the barrel carefully, there's a circlip in a groove that acts as a locater stop against the valve.

The BB follower is plastic. Look at that spring! That's exactly what I need for my Crosman 118 magazine. Think he'd even notice if the gun was only gravity fed?

The BB follower is plastic. Look at that spring! That's exactly what I need for my Crosman 118 magazine. Think he'd even notice if the gun was only gravity fed?

Some valve pics. Rear. The silver protrusion is the valve stem that gets struck by the hammer.

Some valve pics. Rear. The silver protrusion is the valve stem that gets struck by the hammer.

Top. The screw holds a spring that pivots the BB shuttle (for lack of a better term).

Top. The screw holds a spring that pivots the BB shuttle (for lack of a better term).

Screw and spring removed. The shuttle slides right out. It picks up a BB from above and as the trigger is pulled, a transfer bar pivots the shuttle into alignment with the breech. It's a really simple, elegant design. Note: There are no seals on the side of the shuttle-- just an interference fit in the valve body.

Screw and spring removed. The shuttle slides right out. It picks up a BB from above and as the trigger is pulled, a transfer bar pivots the shuttle into alignment with the breech. It's a really simple, elegant design. Note: There are no seals on the side of the shuttle-- just an interference fit in the valve body.

Removed the cap from the front of the valve.

Removed the cap from the front of the valve.

Valve spring and stem pulled out.

Valve spring and stem pulled out.

Ah, here's that bad cartridge seal. Unscrewed the threaded retaining ring.

Ah, here's that bad cartridge seal. Unscrewed the threaded retaining ring.

Used a dental pick to work the crumbling seal out.

Used a dental pick to work the crumbling seal out.

Underneath is a standard 38T/C piercing pin and screen filter.

Underneath is a standard 38T/C piercing pin and screen filter.

Here's what the crumbled pile used to look like. Crosman's part # for the seal is 38-128. It's still available and used today in the Crosman 357 pistol.

Here's what the crumbled pile used to look like. Crosman's part # for the seal is 38-128. It's still available and used today in the Crosman 357 pistol.

Reassembled: Screen, piercing pin, seal, retaining ring.

Reassembled: Screen, piercing pin, seal, retaining ring.

Replaced the cap o-ring with one that looked similar in nitrile. Didn't replace the stem seal. It actually looked pretty good and it operates with 900 psi on it--that really helps keep it closed.

Replaced the cap o-ring with one that looked similar in nitrile. Didn't replace the stem seal. It actually looked pretty good and it operates with 900 psi on it--that really helps keep it closed.

Greased the shuttle's sides to help pivot smoothly and seal.

Greased the shuttle's sides to help pivot smoothly and seal.

A couple views.

A couple views.

Oh, I lubed the valve stem seal with a little Crosman Pellgun Oil. The rest of the reassembly was pretty uneventful. I did refinish four or five of the visible screw heads, removing old screwdriver marks and rebluing. The gun gassed right up and fired 60+ shots without any hiccups. I'll give it back to him and he can finish giving it a shake down.

If I ever find one of these (and for the right price) it would be relatively easy to turn down 8" of 1760 barrel and shoot this with 0.177 cal lead balls. I'd imagine that the accuracy might even be pretty decent but probably not the velocity.

Oh, I lubed the valve stem seal with a little Crosman Pellgun Oil. The rest of the reassembly was pretty uneventful. I did refinish four or five of the visible screw heads, removing old screwdriver marks and rebluing. The gun gassed right up and fired 60+ shots without any hiccups. I'll give it back to him and he can finish giving it a shake down.

If I ever find one of these (and for the right price) it would be relatively easy to turn down 8" of 1760 barrel and shoot this with 0.177 cal lead balls. I'd imagine that the accuracy might even be pretty decent but probably not the velocity.