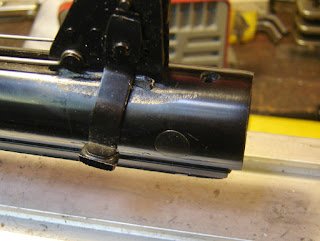

Here are the Theoben conversion parts that I found in my rifle.

The setscrew is threaded through the end cap, fits through a hole in the cross pin and bears on the end of the gas ram.

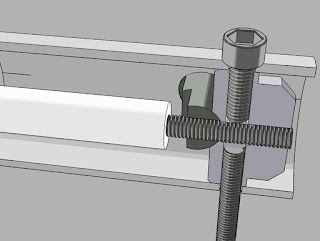

Here's a cutaway view. All the force of the ram is taken by the screw through the scope rail on top and the stock screw on the bottom. This probably explains why my stock screw was stripped at the end. In order to take the stock off, you have to unscrew it. But it's under a small bit of tension, so as you remove it, it's rubbing against the tube with some force. If the setscrew could be loosened before removing the stock, this would eliminate that wear.

I am not crazy about the fact that this conversion bypasses the cross pin.

The stock spring setup.

The spring rests on the washer fitted to the spring guide on the left, and the force is transferred to the cross pin by the washer and the spring guide.

With the stock setup there is no force on the scope rail or stock screw at all.

So my main question is:

Was this really how the Theoben conversion was made on the BSA Superstar, or am I missing some parts that would transfer the force to the cross pin?

And a few followup questions:

If the Theoben setup is the way it's supposed to be, is it ideal?

Would I be better off making a washer of some sort that could transfer the force to the cross pin?

Should the setscrew be screwed in to just touch the end of the Theoben ram, or should it be used to provide extra preload?

I'll have to ask around on the forums...