After shooting the TF79 a bit, there were a few modifications to the stock I thought would be helpful. (Note that this rifle is also known as the AR2078A.)

I had some accessory rail left over from the

Haenel 303-Super project.

Yeah, pretty much the same job.

A few issues immediately arose. Where the Haenel forend was relatively square and blocky, the TF79 stock tapers on the bottom as well as the sides. Didn't have a way to fixture the stock to cut the slot.

Traced the outline of the rail then added some vinyl tape to act as guides.

Gonna freehand the slot with a trim router and a nice sharp bit.

Well, there's no turning back now. I consoled myself by noting that Archer Airguns sells reasonably priced

replacement stocks for this rifle.

Multiple passes and slowly adjusting the depth of the cut

Almost there.

A few really small tear outs along the edge. The stock will be stripped and refinished, so those shouldn't be a huge problem.

Finished the slot with various wood chisels and scrapers. Was a relatively difficult slot to cut, as it had to be parallel, centered, the correct depth...

Test fit. Decided to fix the tear outs now while there was still sawdust on the bench for filler.

Scrounged up some shoe polish and clear epoxy.

The sides and bottom of the rail got a coat of shoe polish. The epoxy won't stick to the polish--it acts as a release agent.

Waxed rail installed.

Mixed the epoxy and added sawdust from the stock.

Pushed the epoxy into any and all gaps along the sides of the rail. Overfilling is preferred.

Pressed additional sawdust into the epoxy.

Gave it a few hours to dry then scraped off the excess.

Still need to fit the ends of the rail to the forend. A half-round at the rear and an angled cut up front would best match the stock lines.

Hogged out most of the curve on the drill press with a milling cutter. Just used it like a drill bit. The benefit was that it doesn't need center contact like a drill bit to feed into the work. The edge cuts efficiently even with overhang. I repeatedly moved the work int he vise, moved the vise, moved the table until I had a passable curve.

This was close enough to finish on a small sanding drum (not shown).

Pretty OK match to the curve for the mounting bolt.

It's not perfect, but it'll look just fine once the stock is finished. Sanded the epoxy filled edges to blend them into the stock.

The front of the rail just needs cut to match the angle of the forend. Marked it with a precision Sharpie. A hacksaw did the trick.

A bit of filing, but it'll be easier to sand the front as one piece later.

Lot more work to be done on this one. I'll keep the replacement stock from Archer bookmarked.

Check back soon.

Needed to screw the accessory rail into the slot. Since the bottom of the forearm is sloped, it was a simple matter to angle the drill press table until all was level.

Needed to screw the accessory rail into the slot. Since the bottom of the forearm is sloped, it was a simple matter to angle the drill press table until all was level.

Skipped over the layout for the hole positions. Drilled through the rail into the stock--this both spotted the holes in the rail and pre-drilled the stock for the mounting screws.

Skipped over the layout for the hole positions. Drilled through the rail into the stock--this both spotted the holes in the rail and pre-drilled the stock for the mounting screws.

Removed the rail, returned the table to zero angle and through drilled the rail for the mounting screws.

Removed the rail, returned the table to zero angle and through drilled the rail for the mounting screws.

Countersunk the heads. Ran deck screws home and the rail was done--for now.

Turned to the other end of the gun. The TF79 stock is pretty short and I need a bit more length of pull. Like to have an Anschutz or Centra adjustable butt plate, but the cost is pretty steep.

Countersunk the heads. Ran deck screws home and the rail was done--for now.

Turned to the other end of the gun. The TF79 stock is pretty short and I need a bit more length of pull. Like to have an Anschutz or Centra adjustable butt plate, but the cost is pretty steep.

I sketched up a few ideas and started cutting aluminum. Started with a short piece of 1" round stock. Ideally, this would've been about a 3" long piece of 1" x 1.5". Didn't have any on hand and didn't want to wait a week. If this proves to be insufficient, I'll remake this piece later.

I sketched up a few ideas and started cutting aluminum. Started with a short piece of 1" round stock. Ideally, this would've been about a 3" long piece of 1" x 1.5". Didn't have any on hand and didn't want to wait a week. If this proves to be insufficient, I'll remake this piece later.

Faced the ends. Important to get them flat and parallel for the next step.

Faced the ends. Important to get them flat and parallel for the next step.

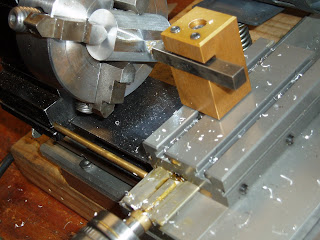

Switched to the 4-jaw and chucked the rod lengthwise.

Switched to the 4-jaw and chucked the rod lengthwise.

Turned a flat

Turned a flat

Flipped the piece 180 degrees--placed the flat against the base of the chuck-and cut another face.

Flipped the piece 180 degrees--placed the flat against the base of the chuck-and cut another face.

Wasn't trying to get the flats the same width, but I did want them parallel to each other. Measured the width at one end...

Wasn't trying to get the flats the same width, but I did want them parallel to each other. Measured the width at one end...

Then the other. Looks parallel within about .0005" over 2". That's some testimony to the Taig lathe's accuracy.

Then the other. Looks parallel within about .0005" over 2". That's some testimony to the Taig lathe's accuracy.

Cutting another face. Now, I want the next opposite side to be exactly the same. Bottomed the depth stop against the carriage after finishing the cut. Flipped the piece.

Cutting another face. Now, I want the next opposite side to be exactly the same. Bottomed the depth stop against the carriage after finishing the cut. Flipped the piece.

Measured the OD and subtracted that from 1"--the original OD measurement of the piece. Got 0.125" (pure luck that it was 1/8") Locked the carriage against the depth stop then moved the stop 0.125" inward. The next cut is finished when the carriage bottoms out on the stop.

Measured the OD and subtracted that from 1"--the original OD measurement of the piece. Got 0.125" (pure luck that it was 1/8") Locked the carriage against the depth stop then moved the stop 0.125" inward. The next cut is finished when the carriage bottoms out on the stop.

Layout time. This is the adjuster block for the butt plate. I want it to fit over a 3/8" steel rod and hold part of the butt pad.

Layout time. This is the adjuster block for the butt plate. I want it to fit over a 3/8" steel rod and hold part of the butt pad.

It'll need a 3/8" hole drilled lengthwise as well as some various anchor and mounting holes. The hole locations are not critical, but they are constrained by space due to the small piece of aluminum rod I started with.

It'll need a 3/8" hole drilled lengthwise as well as some various anchor and mounting holes. The hole locations are not critical, but they are constrained by space due to the small piece of aluminum rod I started with.

Tackle the 3/8" through hole first. Spotted, then drilled.

Tackle the 3/8" through hole first. Spotted, then drilled.

Part of the layout involved center finding for two M4 setscrews. These will keep the block from moving on the 3/8" rod.

Part of the layout involved center finding for two M4 setscrews. These will keep the block from moving on the 3/8" rod.

Spotted, drilled, tapped.

Spotted, drilled, tapped.

Also need two recessed M6 mounting bolt holes. The M6 bolts will attach the block to an as-yet-to-be-crafted aluminum base plate attached to the stock.

Also need two recessed M6 mounting bolt holes. The M6 bolts will attach the block to an as-yet-to-be-crafted aluminum base plate attached to the stock.

Through drilled, then counterbored for the heads.

Through drilled, then counterbored for the heads.

The M6 socket head cap screws are recessed so the heads sit under the 3/8" rod. Tight fit with almost no room for error. This is where that larger piece of aluminum would've made things easier.

More soon.

The M6 socket head cap screws are recessed so the heads sit under the 3/8" rod. Tight fit with almost no room for error. This is where that larger piece of aluminum would've made things easier.

More soon.