My trip to the airgun show in Findlay, Ohio was foiled today. Heading west from Akron, the conditions were getting worse with each passing mile. After twenty miles, it was obvious it was going to be three-plus-hours of white knuckle driving each way. Dejectedly, I turned around and headed home. Hope everyone who can make it has a great time.

Saturday, April 9, 2016

Monday, April 4, 2016

Crosman Model 130 (Metal pump Handle) Disassembly

Hey, remember me? Yeah, I used to blog about air guns before I ran out of space and money, as well as all the air guns available in the valley... Well my buddy Kent came across this Model 130 in a barn and it needed resealing so here I am again. I previously covered the earlier version of the 130 so it will be neat to see the differences.

In good shape but it appears some shade-tree mechanic has been at the innards…

That does not bode well…

That hole should be for adjusting hammer spring tension, but only on guns with a knock-open valve, on this model I suspect it’s what they had on hand?

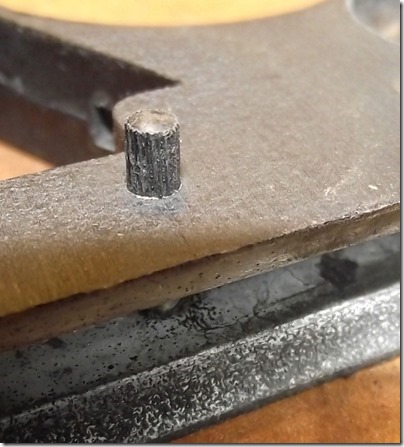

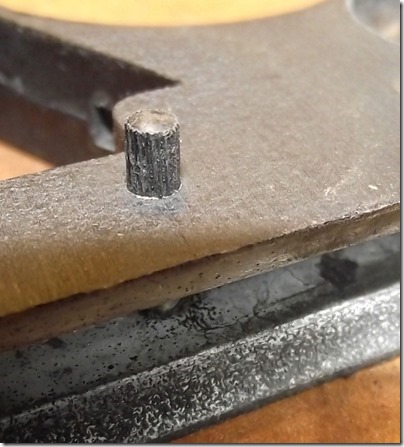

A lot of scratched around the roll pin…

The bolt screw hole had a burr on it that prevented it from coming out until I deburred it.

It looks like they tried to use a tire patch to seal the transfer port. Not the best idea.

This is going to be a pain. The other 130 had an o-ring instead of a pump cup. I’ll have to try and press the brass ring out and modify a 1377 pump cup. Or I’ll machine a new one…

Roll pins only come out one way. Well they come out both ways but one does less damage.

A nice oval piece of spring keeps the trigger from slopping around.

The mechanic inserted a flat piece of rubber between the hammer and the blow off valve because he had no idea how the gun worked.

Notice the dents on the valve spacer.

Now to clean and reseal, hopefully soon.

Update 05/05/16

I cleaned it, changed all the o-rings but didn't do anything to the pump cup other than oil it. Put it back together (which is done in reverse of disassembly) and it works fine. So nothing more to write about this nice little pistol.

In good shape but it appears some shade-tree mechanic has been at the innards…

That does not bode well…

That hole should be for adjusting hammer spring tension, but only on guns with a knock-open valve, on this model I suspect it’s what they had on hand?

A lot of scratched around the roll pin…

The bolt screw hole had a burr on it that prevented it from coming out until I deburred it.

It looks like they tried to use a tire patch to seal the transfer port. Not the best idea.

This is going to be a pain. The other 130 had an o-ring instead of a pump cup. I’ll have to try and press the brass ring out and modify a 1377 pump cup. Or I’ll machine a new one…

Roll pins only come out one way. Well they come out both ways but one does less damage.

A nice oval piece of spring keeps the trigger from slopping around.

The mechanic inserted a flat piece of rubber between the hammer and the blow off valve because he had no idea how the gun worked.

Notice the dents on the valve spacer.

Now to clean and reseal, hopefully soon.

Update 05/05/16

I cleaned it, changed all the o-rings but didn't do anything to the pump cup other than oil it. Put it back together (which is done in reverse of disassembly) and it works fine. So nothing more to write about this nice little pistol.

Subscribe to:

Comments (Atom)