Drilling some tool steel before reaming a 1/8" hole.

Drilling the other end 19/65"

Reaming to 5/16"

Turning a 10 degree taper on the end. A file was used to clean up the end and put a secondary bevel on the cutting end. I did not harden the punch, but may in the future.

A 1/8" dowel pin provides a removeable pilot.

Some 1/8" thick 95 durometer urethane was punched with an 1/8" hole.

I inserted the dowel pin in the hole.

And slipped the punch over it.

Using the arbor press I was able to make a nice concentric seal.

Inserted in the exhaust valve.

The stem was slipped in and then pressed all the way home. I have no idea why I forgot to take a picture of it pressed all the way in, I guess I got excited. The replacement seal stands a little proud of the brass body, I'm assuming it will compress a bit from use.

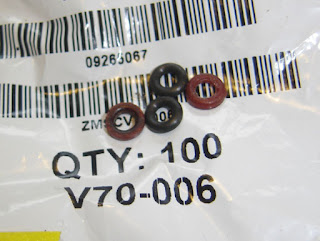

The large valve o-ring was replaced with a viton one.

The two small o-rings were replaced with viton ones.

The valve reassembles in reverse from disassembly.