Turning a new piston head.

Drilling...I tapped it #10-32

Setting the compound to 45 degrees.

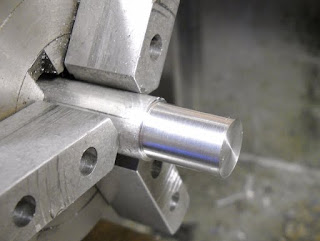

Turning a stem on the piston. When I make the MkIII (very soon) I'll make this and the corresponding hole in the cup larger in diameter and from steel rather than aluminum.

Turning the taper.

Cutting it off a bit long.

Because I'm making a conical countersunk washer I then had to bore it out. There are other better ways to do this but this is where I ended up at the time.

Countersunk for a #10-32 FHSCS

Mounted on a mandrel.

The waste removed.

Fits!

Already I can tell the aluminum isn't up to the task...

No comments:

Post a Comment