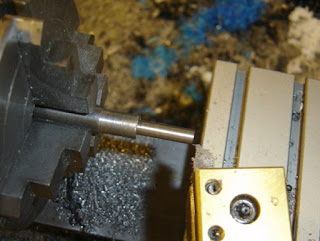

I turned an extra long shoulder that's 5/16" diameter, with a 3/16" shank, and parted off to length, leaving a short 5/16" diameter stub.

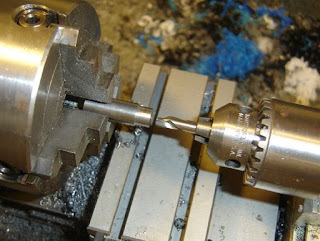

Which I then drilled.

And reamed to 3/16"

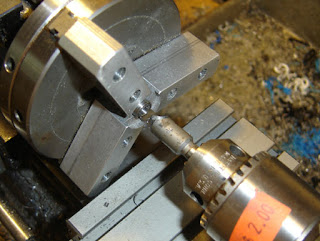

I then parted it off and deburred the cut off side.

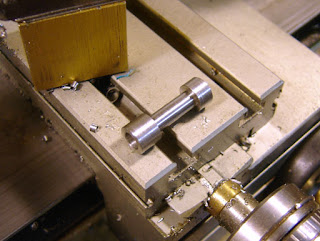

The new pin assembly.

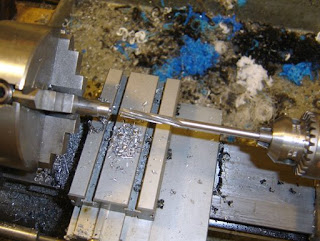

I used a jewelers saw to slit halfway through the bushing.

Then halfway the other way.

This leaves a section that can be compressed by the pin locking screw, which will retain the entire pivot pin assembly.

The head side of the pin in the counterbored hole.

The bushing side.

The rifle pumps up fine now and I feel a bit more secure that the pump force is bearing on the tube rather than the tiny plug screws. The rifle seems a bit underpowered, as I'm only getting about 10 ft/lbs (580 fps w/14.3 gr. pellets) with 8 pumps, although another four pumps gives the same level of power. If I get bored in the future I'll tear the valve down and see if the seals need replacing, etc.

Another old ugly beater restored to functioning condition!

7 comments:

Nick,

As you well know, I'm still really weak in the machining skills and so I'm at a loss sometimes as to when I should be using the 4 jaw vs. the 3. Given the amount of time it takes to center the 4 jaw, it's not my go-to. I see that you either changed jaws during this post or you had 2 Taigs set up. Was there a reason or was that just how it worked out?

DK

If I have to turn steel, if the part is relatively long or needs to be gripped with strength, then I'll usually use the 4 jaw. After a while you get very fast dialing it in.

If it's not a critical operation, or I'm feeling lazy I'll use the 3 jaw. It sometimes just comes down to whatever chuck is on the machine at the time.

Thanks! Any tips for fast centering of the 4 jaw would be appreciated.

I have an article on it here:

http://www.cartertools.com/fourjaw.html

Basically having a dedicatred indicator mounted on the lathe really helps as you don't have to waste time getting one out and set up.

And practice...

That's dedicated...

Hello Nick,

The 312 only has 1 small hole to release the air.

The later Bens had 2 holes that let the air come out faster and more complete.

So pumping to 20 will only let the same amount of air in the chamber.

That being said your gun may benefi from a good cleaning or some smith work...

From Tony392

I see by these articles alot of you out there are machinest.I have a benjamin 312 rifle with a two part bolt. I need the handle for the bolt to be able to enjoy the rifle as it was ment to be used. Can anyone out there help me. I am not asking you to do it for free.

Post a Comment