I chucked up a piece of L shaped steel in the 4 jaw chuck.

Turned a shaft on it.

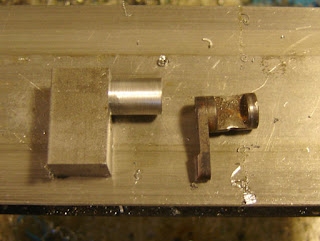

Looks like a safety already.

Sawed off the waste.

I put it backwards in the vise, alas, when cutting the notch for the safety plug.

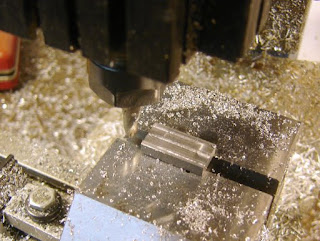

Milled it thinner.

Trimming away.

A rough, mirror image safety.

I rounded the corners on the belt sander, then milled away a bit more to make the lever.

I used the checkering file to serrate the lever.

Well, it works, but it's the wrong way around.

This is the guy who distracted me. But he makes a good gun rack.

There's still a bunch to do, assuming I can live with a backwards safety lever.

I drew up the bolt today, and hope to make it this weekend. Then I'll think about the final design for the breech cover.

I did run some rounds through the gun. Initial numbers were in the low 300's, at which point I realized I was loading .177 pellets in a .22 rifle. Distractions...anyway, it's shooting around 580 fps with 10 pumps (14.3 gr.), which is a little low. I hope that a new transfer port seal and a new bolt will speed it up a bit. We'll see.

4 comments:

nice work. i have a 140 with a torn o-ring. the ring that goes on what would be the bolt i suppose. any ideas of where to get one that will fit correctly?

For pnuematic guns you can use plain old buna o-rings. Most good hardware stores will have them, failing that anyplace that sells hydraulic type stuff. You can of course order them online from most industrial suppliers.

For full reseal kits you can try Bryan and Associates, Mac1, Precision Pellet or JG airguns.

http://www.bryanandac.com/

http://www.mac1airgun.com/

http://www.airgunshop.net

http://www.jgairguns.biz/

Tell them I sent you.

Nick

i need a piston for a Crossman " 140 ", I tryed all your webb pages, 0.

Any ideas ? ? w2crunch@aol.com

thanks, got parts I needed from www.bryanandac.com, works great.

Wally, w2crunch@aol.com

Post a Comment