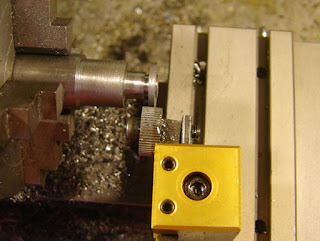

Turning the shoulder.

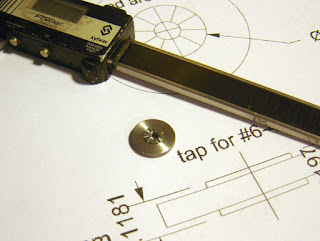

I used the parting tool to create some clearance so I could get the caliper in to measure the other shoulder diameter. Then I drilled for a #6-40 thread.

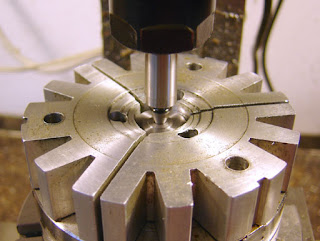

Tapping the #6-40 thread.

Ready to knurl.

I broke the edges after knurling.

Using a pointed centerfinder to determine center. I just used my fingernail to make sure it was lined up, not a high tolerance setup...

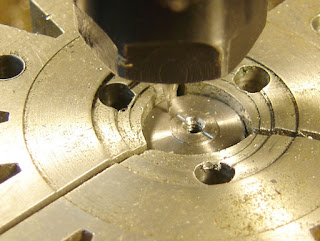

Cutting the elevation detents with a 1/32" ball end mill.

Done...

The grooves ended up being off a bit as once again I forgot how to read the stupid Sherline rotary table dial. But hey, he's happy with the part and the gun is now complete.

"30" actually means 30 tenths of a degree, or 3 degrees. Why not just make the handwheel say "3"? I have now written the proper markings with a sharpie on the dial. Of course it's really my fault for not remembering since the last time I made this mistake...

2 comments:

Do you have experience in turning down 2260 barrels to fit the 2200 breach?

I don't, as yet, have any experience doing so.

Post a Comment