First up was the missing spring and ball detent for the safety. I have a large collection of ball bearings and found the correct size.

The spring was scavenged from an empty (make sure it's empty! I find putting it underwater and pulling the gas valve lever until no more bubbles come out is a good test) Bic lighter. Then cut to length.

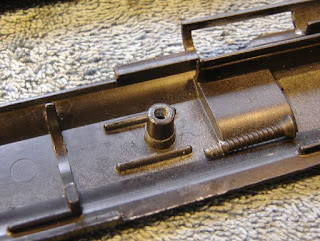

This picture shows that you must have the pivot aligned as shown. Again, more for my reference.

The foam oiler and the piston seal were in poor shape.

A seal kit from Daisy (for the 717, but it fits the whole range of 7xx pistols). $1.00 is what they charge. Contact them for an exploded drawing and parts price list.

The valve o-ring was in terrible shape as well.

I removed the valve nut/assembly.

Then I gently pushed the c-clip off the valve stem with a screwdriver.

And pried it off.

The valve seal itself looked good, which saved me remachining the redesigned valve that Daisy now uses.

I replaced the small o-ring which seemed stretched out.

The plastic seal on the right was fine, it's really a seat for the spring.

The valve body o-ring was past it's expiration date.

So it was replaced with a new o-ring.

The c clip was squeezed back on.

One of the screw holes was stripped out.

So I filled it with JB weld.

I left it to cure overnight, then centerpunched it.

Drilled it out to the minor diameter of the screw.

I did the same thing with one of the grip screws. I'll order the proper screw next time I get parts in from Daisy, but for now a fine thread machine screw works well.

Adjusting the piston headspace.

I turn the piston counter clockwise to decrease headspace until I just a slight resistance when closing the pump arm.

After sighting in (I had a spare Daisy sight to replace the missing one. $2.50) this was my first shot at a new target. Further shots weren't quite as impressive....

The finished air pistol, with paint touched up a bit.

I chronied it and am getting a spread of 288-297 fps with Crosman wadcutters. Not bad! Total cost of the repair was $3.50 plus a few 10 cent o-rings and a tiny amount of epoxy and airgun lube.

2 comments:

It is (in my case)always the same.

in 1980 I purchased My Daisy 722.

I´ve repeared her many times, but

las time I saw that the back

aiming device was broken,I did

All he pieces together, but some-

one separed in two the pieces

and now I´m an in pain soul ¨cause

I can´t find the inner parts.

with her ten inches barrel she´s

a cannon, hope Í´will find all the

pieces for assembling her

I'd pay $20 to get mine back ip and running. I loved that gun. I'm just not the guy you want tinkering with the internals.

Post a Comment