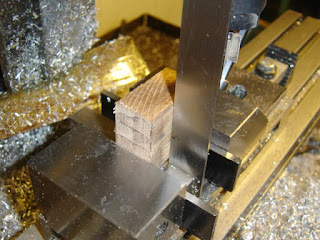

A small rectangular walnut block gets squared up on all sides.

The top speed of 5000 rpm on the manual Taig mill works well with router bits.

Finding the edge.

Milling a 3/8" wide channel with an endmill.

Spotting for the screw hole that attches it to the pump arm.

Rounding over the edges.

Fits like a glove!

Drilling for the screw hole.

I drilled just deep enough to spot the pump arm for the screw threads.

The pump arm was drilled and tapped for a #8-32 screw.

The walnut block was counterbored.

And the two were screwed together.

The walnut block makes it easier to pump, as the 3/8" wide aluminum really starts to dig into your hand after a while. The other benefit is that it functions like a palm rest, allowing you to hold the carbine comfortably and steady.

I didn't bother sanding and finishing the walnut or the pump arm as there are going to be many opportunities to ding, scratch and otherwise abuse them throughout the build. Better to only do the finish work once!

No comments:

Post a Comment