Chucked a Crosman 22XX barrel in the lathe jaws and pushed it into the counterbore in the breech.

Just using the barrel for alignment. Used several setup blocks as well as some shim stock underneath the breech until the through hole was centered up on the lathe's headstock. I need to paint that window frame in the background...

Then I clamped the breech down to the crosslide. Aluminum sheet was used between the setup blocks as well as the clamps to prevent marring the breech.

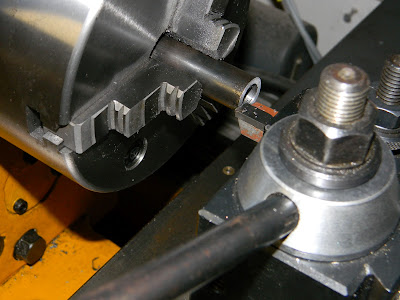

Removed the barrel and mounted a 5/8" center cutting endmill in the lathe chuck.

Very slowly shaved metal to produce a stepped hole at the front of the breech.

No measurement as the depth isn't critical. About 1/4"+ will do.

The plan is to sleeve the skinny 7/16" OD Crosman barrel for additional muzzle weight and stability.

The step will accept the end of a 5/8" OD barrel sleeve. The sleeve will be made from the piece of DOM tubing on the right.

The DOM tube is both too long and too small in the ID for the Crosman barrel to fit into.

With a parting tool, I cut about 3" off the end of the tube.

Then through drilled with a long 7/16" bit in the tailstock. Had to flip the workpiece around and drill from both ends to the center.

Cleaned up the ends of the tube. Not shown: After drilling, a 7/16" reamer was run through the tube for clean up.

Couldn't take the humidity outside any longer. Brought the tube indoors and wrapped the Taig bed with foil protection and polished the tube to 400 grit.

Test fitting.

Barrel slip fits into the breech. It'll get set screws later.

Sleeve installed over the barrel. Could've just butted the tube against the end of the breech, but recessing the end is cleaner.

More soon. The next step is make or break.

4 comments:

Looks good. Just a question, couldn't you have used the lathe to drill your breech, the same way you just used it to bore it for the barrel?

Yes, I could've used the lathe if I had an independent 4-jaw chuck. Don't have one for this lathe yet--and I wanted to do it with existing equipment on hand.

Great work so far, cant wait to see more.

Hi

Is it possible to covert from .177 yo.22?

Could you tell me the parts requirement

Post a Comment