I do apologize for not posting more, between work, kids and a terrible flu for the past few weeks I’ve been useless. Rather than posting nothing I thought I’d crack open a Crosman model 338 I bought a while back, just to see how it goes together. I’m still messing with the Crosman 105, having problems with it. In fact I’m only batting about 50% right now with airguns. Maybe I’ve lost my mojo or more likely I’ve been lucky up to this point. Possibly I need to stop playing with CO2 and MSP guns and crack open a springer…

It’s a copy of the Walther P-38.

The hammer is part of the casting, it’s not a replica by any means.

CO2 cartridge holds the right grip in via spring clip.

Hammer spring in the grip.

It’s stout, and a bit difficult to replace without levering it back in.

One screw for the left hand grip.

This exposes one of the two screws that hold the body together.

Removed.

Things sort of spring apart at this point.

Safety on.

Safety off.

The barrel shroud and barrel lift out.

A setscrew holds the barrel lug to the barrel. This can be used to set headspace.

Everything somewhat sprung.

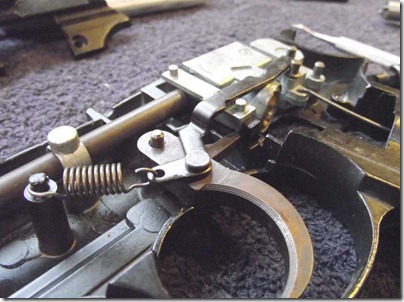

Other side of the riveted together trigger assembly and transfer bar.

BB shuttle mechanism.

Potmetal piece lifts out, notice the cutout for the passage of gas.

BB shuttle. There’s a small insert to take the wear of the trigger bar that lifts the shuttle.

Valve assembly.

Hammer assembly. Closest pin is the pivot, others are pressed/cast in place.

Standard piercing pin setup as found on most Crosman guns of this period.

The seal is worn. I replaced it but I’m still getting a leak right there (gas flowing out between seal and pin). Not sure why. Could be the latest seals I got from Crosman are bad or possibly I need to tweak something. This comes on the heels of a similar problem with the as yet unfinished model 99, so I am wondering what’s up. I never had such problems before. I’m sure I’ll figure it out eventually.

The 38 valve tool I made unscrews the valve.

Pretty simple. Not shown is the valve end seal – I left it in place.

Reassembled. Notice the position of the transfer bar. You have to sort of hold it in place while snapping the side back on, and use a tool to push it into alignment as you close it. requires 3 hands but becomes easier with time.

Notice the position of the transfer bar above the pin pressed into the hammer. Now I just need to figure out why the CO2 piercing pin seal is leaking...

17 comments:

Trigger pull is a hard but being used to a Glock it's not a problem. Disassembly and oiling helps alot.

I have taken mine apart...I have a spring left over... its round and has one end pointing up and the other strait! where does it go!!!! plese help

Well that spring goes under the trigger, flat end attached to the weird gate, and up pointing end goes in the hole on the trigger. And thats My question, just what is that gate that goes around the end of the Barrel actually used for? Tim D.

Well that spring goes under the trigger, flat end attached to the weird gate, and up pointing end goes in the hole on the trigger. And thats My question, just what is that gate that goes around the end of the Barrel actually used for? Tim D.

i have a 338 auto airgun. when i try to install the c02 cartridge all the gas leaks out. can you please give me any ideas of what i am going to have to do to repair this? i have looked over all of your pictures and feel very comfortable taking it apart and putting it together, but i would just like a heads up on what i am getting into to fix the leakage problem. are there still parts available for this airgun? it is from the early 1990s and it is only now developing this problem. thanks for any help. Jim

I have the same problem after years of no use, and the whole seal assembly was too old to salvage, you can replace items if you find a dealer who sell parts.

Found source for seal kit, it is AllianceHobby.com and just got, so hopefully it will solve leaking valve problem.

What is really funny finding out the 338Auto as used in the short lived Crosman Z77 Uzi. Remove the plastic Uzi housing and inside is an almost complete 338Auto minus the barrel and shroud. I guess it was easier and cheaper to use the 338Auto base add a longer barrel and put it in a plastic housing then to design a new gun.

The Co2 end seal is crosman part number 38-128 and is still used in some crosman guns. It is available from many sources including crosman. The valve stem seals are 38-130 and 357-041. The 357-041 has been obsoleted by crosman and is difficult to find.

I have the same problem, replaced the seal, my question is the screen has one flat side and one rounded side, which way does it go?

Any one know where (or even if) I can find and purchase a cartridge seal for around the piercing pin? Mine seems to have hardened or crack and empties a cylinder completely before I can tighten the cylinder plunger down far enough. All help appreciated. Thank you. rk

Call Crosman, it's the same seal as used on the 357 I think.

buy the seals at airgunsseals.com they have the seals for my 338

Crosman still sells the seal and piercing pin/disc.

Piercing pin new part number T4-041 $2.64 (old part number was 38A027)

Seal 38-128 $1.15

Shipping is flat rate of $4.00

This is an outstanding post, Thanks Nick. It really saved my rebuild project by providing those great pix of the safety spring. I too have a piercing pin problem after replacing all seals. For some reason I now cannot actually pierce the cartridge no matter how hard I screw that thing down. Your post and pix confirm that I have all the stuff in the correct order. Any suggestions??? Thanks all.

I should revisit it, I'm not sure why but I suspect it's a difference in seal thickness or geometry.

Nick

Hey guys I ordered the repair kit from JG air guns. CRS338SK. I have a black o ring that I don’t see in the valve in these pictures. Any idea? I think it does with the rod and spring valve.

Post a Comment