I really didn’t know what I was dealing with…

Levering out the brass ring (I used a small screwdriver in the slots) so I could get a better look in the cavity for the seal. Notice the pot metal fracturing. I had to use gravers to remove the excess metal trapping the ring. In hindsight I suppose I could have left the ring in place.

Although with the ring removed I was able to measure for the diameter of the seal. The ring got beat up in the process. I wonder if Gamo just swaps the whole valve assembly when they service the pistols?

Drilling the seal hole.

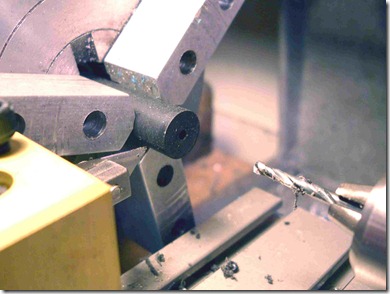

Turning down to diameter.

Cutoff. The first one I made was about .05” thick, later I made another than was about .04” which worked better. The seal is basically just a flat disk.

Seal in place.

Brass ring pushed in. In theory it should stay put.

Testing the assembly with a used (empty) cartridge. Reassembly of the pistol was in the reverse order of disassembly. I managed to flip the “teflon” exhaust seal around and at first the pistol wouldn’t function, I disassembled the pistol several times and finally realized that I had it flipped. It now functions normally and holds gas. Once I get some clips I’ll test it out and see if there are any other problems.

11 comments:

Good try Nick! I'm trying to do this too. Thanks for the information :)

What material did you make the new ring out of, and what was the OD/ID dimensions?

Thanks

90 or 95 durometer urethane rubber.

Didn't write down the dimensions at the time, just make to suit.

Hi Nick,

Came across your blog whilst trying to solve this problem.

I've bought a new seal for a PT80 and assume it's meant to fit behind the brass ring. I'm not a metal worker and don't have an extensive collection of tools. I don't want to even think about disassembling the gun to get the brass ring out.

Can you offer any suggestions?

Regards,

Dave

Send it in to Gamo for service?

Hi Dave C,

I was able to replace that seal without removing the ring. I made something like a hook with flattened tip from the steel wire and scraped out the leftovers of the original seal from underneath of that brass ring. Then I put the new seal in by using a small screwdriver and another hook to tuck the edges of the seal under that ring. Just make sure your screwdriver is not sharp otherwise you will destroy the seal. It was not that hard because I took the pistol apart and had the valve assembly easily accessible. I don't know whether you will be able to do it without taking the gun apart.

Good Luck!

KP.

Thanks KP, just noticed your reply. Will try your suggestion!

D

I have just replaced my co2 seal without taking anything apart.

I used a dental curved pick to gently remove the damaged bits of the old seal, took some effort to get it all out as it is not really possible to see under the brass ring. Putting in the new seal was an ordeal, I had to stop and have dinner. after 10 minutes. The gun was clamped in a vice between some firm foam to prevent damage and a strong light directed into the hole. I put a little olive oil on the seal and in the chamber and coaxed the seal under the brass ring with some small round hex keys, The last bit I had to use a small flathead screw driver to bully it under the ring as it kept crinkling up. The lube kept the screw driver from cutting the seal, After some stress it finally went in. It works fine now , back in action. If I had to do another one I would round the edges off the screw driver. Regards Tim. from UK

a friend asked me years ago if i could repair his gamo , there were no seals i could find , so i used a small O ring to fit around the tube which punctures the cartridge . i put some prit non - permanent glue on it to hold it in place . holds gas for days

Hey where do I get a seal for my gamo pt80 on the hammer build seal

Post a Comment