The 2100, you can download the manual and exploded drawings from the Crosman site.

This is where you pour the BBs in. It's also where you pour them out before working on the rifle.

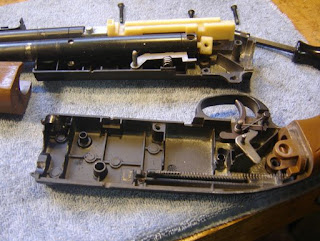

I removed those three screws.

Like the 760 and the 66, the gun sort of falls apart after you pry it open. It's hard to show every step because so much of the reassembly involves both hands.

Notice the small spring (766A020) at the top fits against that cutout.

This is the way the trigger spring goes.

The sear can be retracted and the tube removed.

This shows the trigger relationship to the sear.

The small white plug (766-030) retains the hammer spring.

Remember that small spring? Here it is in its natural habitat fitted against the 766-019.

The bolt and 766-013 plastic thingy (Crosman doesn't give a name for it).

The hammer parts.

I unscrewed the forearm.

Mostly disassembled...more to come.

19 comments:

can you check to see if it has a rifled barrel?, I have a 2100b that's smoothbore

Thanks

Unfortunately I did it for a friend who already has it back, so I can't check.

correct me if I'm wrong the remington airmaster I believe is a

2100 with a black stock and forearm

also what to you use to lubricate pivot or hinge joints- also what to you use for triggers

I think so?

I just use light oil or pellgun oil, sometimes lithium grease or such.

it's a rifeled barrel, the strage think is that it can shoot steel bb's and normal pellets.

And yes it's the same as the remington airmaster, the airmaster has a nicel plated barrel shroud.

Mark

who ever posted this information and photos of the crosman 2100 is a freekin genius! I opened my 2100 and the thing just blew up!! not a hope of putting it together till I found this blog, muchu mucho THANK YOU

Hello,

I have the Remington Airmaster 77 and was searching for opened photos- thanks!

I want to do a trigger job on it. Have you done a trigger job on yours, (or a similar rifle), and do you have any tips or thought about what you did and/or would recommend?

Thanks!

I'm not sure much can be done to the trigger other than playing with different springs and polishing the surfaces for smoother action. There's likely some info on the Crosman forum about it though.

Thanks for the picture of the hammer part! I took my gun apart 15 years ago and ever since the trigger wouldn't engage. I must have lost the pin and not realized it.

I just went into mine since it wouldn't compress anymore. Article sure is a blessing. Have one question. What does the forearm detent, 766A094, do?

Thanks, vjpca@yahoo.com

It locks the forearm in place so it doesn't fall open.

this article saved me today! i took my gun apart to fix the loose stock. it had a crack in it so i superglued it and it was such a pain to put back together but i did it. the only problem was i couldnt find where the tiny spring goes. i tried putting it on the bottom of the peice its supposed to go on but it didnt work. so i just said screw it and put it together. then i took it apart again because im a perfectionist and put it in a different spot near the trigger put it back together, pumped it cocked it, and it wouldnt fire! so i took it alll apart again and it completely exploded on me because of the pressure i could not release. i gathered all the parts and put it away for a few hours. then i found this and it showed me exactly where the spring goes! i was so happy. so now its finally all back together and i could probably assemble this gun blindfolded ive done it so many times today. such a helpful post though! does anybody know where i could find a wooden stock and forearm though?? any tricks for achieving higher FPS?

Absolutely brilliant. The pump cup of my Crosman 2100 came off. Followed the diagrams posted here to complete disassemble, fix and reassemble without any problems -- and I'm a total newb. Helpful hints, to keep things from exploding, after removing three main screws, hold one hand (down) on the barrel and one (pulling up) on the stock (screws side up); slowly wiggle the stock up, it should lift half the receiver (casing) up with it, leaving all the parts where they below and everything (nearly) in tact. My trigger assembly lifted up with the receiver attached to the stock. I did the exact reverse on re-assembly and only needed two hands; no problems (other than lining up the safety and receiving hole).

Thanks for such a great and detailed post.

Awesome blog dude thx

Awesome blog dude thx

Barrell is rifled. I just put new orings on my 2100 and now it pumps up real nice and quick again and holds the pressure. Doubt I could have gotten it back together after it fell all aprt upon disassembly without this pictorial.

Nine years later, your pictures are still doing some good. It helped me out with the placement of a few of the parts when putting back together a Remington AirMaster 77. Thanks!

Thanks for taking the time to create this post with pics, you just saved my bacon!

Does anyone knows were I can gats parts for the 2100 model, I need a pin and a spring 766 044 & 744A020 somehow the gun is available at crossman.com for purchase but no individual parts available for purchase.

Post a Comment