The Steel Breech is an inexpensive upgrade.

You just take the pistol apart, and put it back together...

Add a shoulder stock (I bought two for the price of one through the online airgun classified pages)

The only modification to get to this point is to drill the barrel band/pump tube plug (part #1300A006) out to 7/16"

Pushing out the roll pin that retains the barrel band unit.

Just an ugly plastic part. The general idea of my project, overall, is to replace any plastic with metal.

I took some measurements and made some simple drawings. I decided a 3 part assembly would replace the one part unit.

Facing a length of aluminum rod.

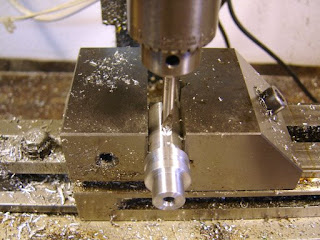

Turning the diameter for the plug.

Filed and scotchbrite-ed.

I flipped it around and mounted it true in the 4 jaw chuck, then cut it off to length.

Turning a smaller diameter for the actual barrel band.

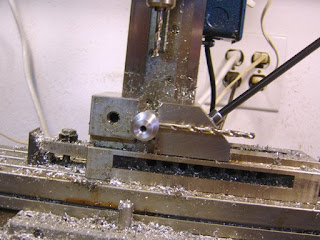

Drilling for a #10 screw thread.

Tapping with hand power, using the lathe for alignment.

Picking up the edge, so I can find the center line.

Picking up the end.

Spot drilling for the roll pin that retains it in the pump tube.

Drilling for the roll pin.

4 comments:

Hey Nice work what kind of lathe is that. The plate in the back of the chuck looks like a front rotor disk with all the holes, like one on my 1000 yamaha virago.

It's a Taig Lathe. The disc is an aftermarket index plate I make, it allows dividing work. It is handy if you have a spindle mounted on the cross or milling slide.

Will you be selling these if so how much, nice work. Thanks Robert

I won't be making aftermarket parts any time soon, still learning the ins and outs of airgunsmithing. Maybe in a few years.

Post a Comment