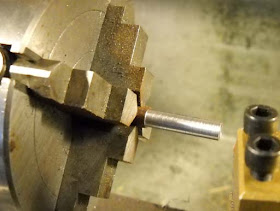

Turning down some mild steel to 5mm.

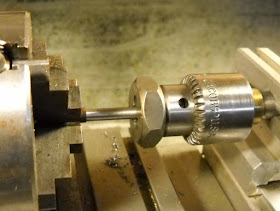

Threading 5mm x .8

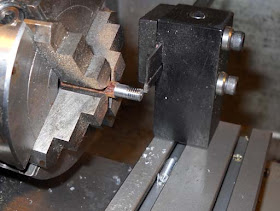

Cutting off.

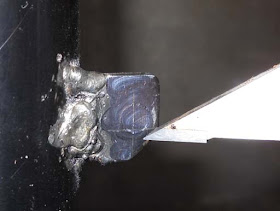

Threaded into the misaligned screw hole.

I soft soldered it in (with Tix Solder

Cut nearly flush.

Peened.

Filed flat.

Aligning the tube.

Picking up the screw hole centerline with the head of a 5mm screw.

Marking centerline.

Held vertically, same thing.

This is where the hole should be.

Setup on the drill press.

The hole drilled. Unfortunately my solder job let go (due no doubt to the fiery distraction while soldering) and it turned slightly in the threads. That is it's held in but could rotate.

So I added a few punch marks to keep it in place. It's not going anywhere. I hope. I tapped it 5mm x .8 and that I could tap it says to me that it's in there solidly.

I tightened up a screw and the plug seemed to be holding fine. I later found a rather large electric soldering iron in my collection of tools so I flowed the solder again, now it won't move, which is good.

Look at that! The screw head is where it's supposed to be.

The misaligned screw is the existing one, the straight one is my repair.

Again, the left screw is the repair.

Oh yes, there will be more to come. Next up is cleaning off all the asphalt/grease/oil/dirt from every part.

No comments:

Post a Comment