All clean...

I decided to minimally lube it, so a very thin smear of heavy tar on the spring.

Some moly on the top hat & washers.

A thin smear of moly on the piston. I just wanted to test for function and make sure the repairs held. Plus I figured I'd see what it did with the original o-ring and breech seal before replacing them.

After cleaning the trigger unit in a friend's ultrasonic cleaner I used some Starret "mouse milk" instrument oil.

The trigger unit is easier to replace when cocked.

Someone had modified the sear.

They rounded over the top. Why? I have no idea.

Using a punch to wiggle the shims back into place.

Then I did some testing. The stock screw tab repair held like a champ. The barrel hasn't moved. 2 good things. Velocity was down though. Before working on it it was at about 760 fps w/ 14.3 gr. pellets. After cleaning and reassembly velocity dropped to about 720 fps w/14.3 gr pellets.

I assume that cleaning out all the caked up lube reduced the ability of the worn o-ring to seal.

Also the minimal lube likely increased drag on some parts.

The other issue was that it wouldn't always catch when cocking. Not an ideal situation.

What would happen is it would fire several times fine then fail to catch. If I then clicked on the safety and pulled the trigger it would click and then it would catch when cocking. I was a bit puzzled so I asked on the Yellow forum. The answer as to what was happening was indeed found here on the Straight Shooters forum. However the trigger parts I had did not look modified or polished as that posters did. Another guy emailed and suggested that I tighten up the trigger weight spring screw. That did indeed fix the problem. So too little tension on the spring allowed that condition to occur. I fired a number of shots after adjusting and it never once failed to cock.

I tore it all apart again.

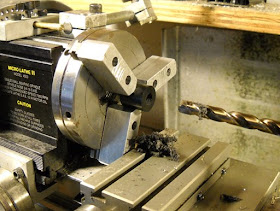

Machining the new breech seal. They're $3.00 from Maccari and I wish I'd bought one last order. But I didn't.

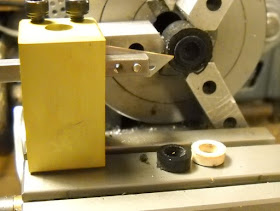

I wanted to try something new for cutting off the urethane. Some mini boxcutter blades.

It worked like a champ.

Just a single screw holds the blade to a stem.

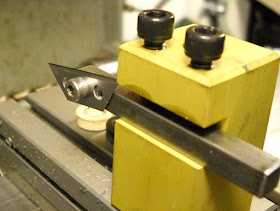

The new seal. I made it just a hair thicker than the old one.

I also replaced the o-ring on the piston with a #213 buna o-ring. I'm guessing that the old one was something harder though and I may get a polyurethane or viton o-ring in that size later on.

I also tried out Derrick's secret lube, Buzzy's Slick Honey

Put the rifle back together and fired about 50 shots through it (and no failures to cock). Velocity was about 773 fps. on average. So the new o-ring and breech seal as well as being a little slicker helped a bunch. I want to shoot a couple of hundred rounds through it before I pronounce it done though. Next I need to make some screw cups and repair the wallowed out screw hole in the stock. I could use a good scope mount as well as a cocking handle. The 80K has a short barrel and it's tiring to fire many shots as you don't have as much leverage.

What a great job Nick! You really seem to have pulled this thing back from the brink. But... I miss the full-size photos. Hope you go back to the old method of photo-documenting - it's nice to see close-up detail of your work.

ReplyDeleteAll the pics seem the same as they always have been. I usually edit them to be 512 px. wide. You can click on the pic and it will open up that size.

ReplyDeleteAh... Went back and checked. It's Derrick who posts the larger pics. My mistake. I should have said "Nick, ever consider posting larger details? It's nice to see the work Derrick does "close-up" I'd like to see your work that way too."

ReplyDelete:-)

I try and keep things small, both for the 10% of people who read the blog with dialup and those with slow DSL. Also I'm at 1/3 of the storage limit right now and I don't want to use that up. If all the pics were twice as big I'd get to the limit sometime next year. But it's mainly that 512 is a good picture size.

ReplyDeleteHow big a screen are you looking at the blog with and at what resolution? You could see what the blog looks like at 125% or 150% magnification in your browser.

But as with all things it's a compromise.

not too sure about the o-ring you put on the piston instead of a proper piston seal...any of the original fitment piston seals or any custom aftermarket one is going to develop more power?they tend to fan out and generate a petter compression but maybe you had a reason that i didnt read in an earlier posting

ReplyDeleteThe piston in the gun was aftermarket and used an o-ring. I wish I had the original piston...

ReplyDeletewould be worth sourcing a new piston, fit a proper factory seal or a good aftermarket one.... the hw80k ended my search for the ultimate. gave away my theoben eliminator to the brother to make room for it. only produces around 18ft lbs over the chrono but thats loads for what i need it for

ReplyDeletewhen will you be posting part 7... like to see the finished performance please.

Ive got a brand new hw80 piston with seal if you fancy a swap

ReplyDeleteIf your intrested ive got a brand new hw80 piston with seal that id swap for the piston?

ReplyDeleteThanks for the offer, but I like the oddity of the Venom piston - it's a little piece of Airgun history.

ReplyDelete