The cylinder plate pops off.

Nothing special about the valve tube.

My valve tool may need some refurbishing…

Crosman uses quad seals here. These seem pliable and will be reused.

The #38-128 end seal is deformed and clearly not up to the task anymore. Luckily I had a few spares on hand.

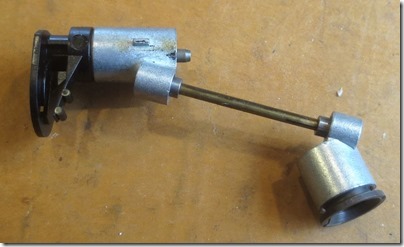

The guts.

The #38-130 o-ring has given up the ghost. I replaced it with a 009 viton o-ring. Urethane would be better.

Not wanting to place an order for parts or spend more time making a seal than the gun is worth, I flipped the #357-041 valve seal over. It was still pliable. It had a scratch in the face that could have made the gun leak.

The gun went back together without a hitch, I suppose it’s possible that the latch support could shift, but it seems to lock up fine without play. It’s held gas for 5 days and shoots as accurately as one would hope. I didn’t chrony it because of general laziness.

Great article and good photos. I'm rebuilding mine again, and found your blog. Airguns are my hobby, and I have collected a few over the years. Just found a S&W 79g at the pawn shop. Have you done a rebuild for it yet? Thanks, Mike W.

ReplyDeleteHow to open valve, there is a nut from brass, that is very soft?

ReplyDeleteSlotted tool for the nut, build one yourself or maybe baker airguns has one.

ReplyDelete