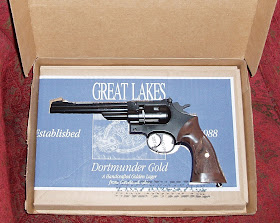

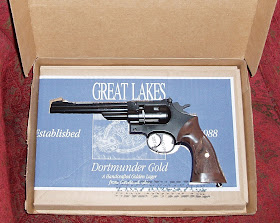

Bought a friend a super clean Crosman 38T for Christmas. Actually bought it for him almost eleven months ago. That's some crazy early shopping, but you buy them when they show up. Besides, he'll be a ten year old kid all over again. Took it home, gassed it up and it worked just fine. Forward eleven months, Kathy and I are ready to wrap. At the last moment, I decide to gas the gun up and give it to him charged. Yeah, you know it. GAHHHH! Almost violated that "do not give non-functional presents" policy.

Quick tear down. We've covered 38T (and 38C) guns

several times on this tawdry blog.

So, I suppose many of these pics are more for my reference to bring me back up to speed on this model.

Before gassing up the gun, Fortunately, I'd given the piercing pin a shot of Crosman Pelgun oil before installing the 12 gram CO2 cartridge. Fortunately--because the oil sprayed out at the point of the leak.

The oil pinpointed the leak at the seal between the valve and the copper gas tube.

Removed everything spring loaded that had potential to shoot across the room.

Pulled the cylinder indexing pawl mechanism.

just some additional pics

The red light indicates the location of said leak.

Crosman calls this a "gland seal". Oh kaaay.

The "gland seal" at the opposite end was just as bad. A close look at the gas tube showed that it was in pretty poor condition, too. It looked cracked at the valve end.

The next morning, a trip to

my favorite neighborhood hardware store (remember those?) netted several various pieces of brass and copper tubing. Thanks Carl!

Cut and faced a 2.25" section of the 1/8" diam. copper.

Started to bell one end with a 30 degree point.

Bench block held the tube. A small steel rectangle under the block allowed me to hammer a wider point (60 degree) into the end.

Then, a couple strategic taps with the hammer, one end was finished.

Cut the bad piece in half. It's the only way to remove the nuts and washer.

Installed on the single-flared-end tube.

Then repeated the flaring step. Not having any 30 year old Crosman "gland seals" handy, I opted for o-rings. I think that's an #A007 on the left and #A006 on the right.

Though there wasn't one there originally, it looks like the valve-end nut is cut for an o-ring at the end of the thread. I added an #A011. It sure won't hurt.

Test fitting proved my eyeball method of sizing the copper tube length was a bit shy of the mark.

So, I cut the short tube in half, removed the pieces and made another. Why do it once when you can do it repeatedly until it's right? Anyhow, reassembled the gun, gassed it up and it leaked CO2 even faster than the first time. The leak was at the exact same spot.

A bit of cursing and a night's sleep later, I replaced that #A006 o-ring with a smaller #A005 then put another one between the small washer and the nut.

Like so.

Reassembled yet again, shot a couple CO2 cartridges through to test and it's gassed up and ready for gift wrap.

Merry Christmas everybody!

Quick tear down. We've covered 38T (and 38C) guns several times on this tawdry blog.

Quick tear down. We've covered 38T (and 38C) guns several times on this tawdry blog.

So, I suppose many of these pics are more for my reference to bring me back up to speed on this model.

So, I suppose many of these pics are more for my reference to bring me back up to speed on this model.

Before gassing up the gun, Fortunately, I'd given the piercing pin a shot of Crosman Pelgun oil before installing the 12 gram CO2 cartridge. Fortunately--because the oil sprayed out at the point of the leak.

Before gassing up the gun, Fortunately, I'd given the piercing pin a shot of Crosman Pelgun oil before installing the 12 gram CO2 cartridge. Fortunately--because the oil sprayed out at the point of the leak.

The oil pinpointed the leak at the seal between the valve and the copper gas tube.

The oil pinpointed the leak at the seal between the valve and the copper gas tube.

Removed everything spring loaded that had potential to shoot across the room.

Removed everything spring loaded that had potential to shoot across the room.

Pulled the cylinder indexing pawl mechanism.

Pulled the cylinder indexing pawl mechanism.

just some additional pics

just some additional pics

The red light indicates the location of said leak.

The red light indicates the location of said leak.

Crosman calls this a "gland seal". Oh kaaay.

Crosman calls this a "gland seal". Oh kaaay.

The "gland seal" at the opposite end was just as bad. A close look at the gas tube showed that it was in pretty poor condition, too. It looked cracked at the valve end.

The "gland seal" at the opposite end was just as bad. A close look at the gas tube showed that it was in pretty poor condition, too. It looked cracked at the valve end.

The next morning, a trip to my favorite neighborhood hardware store (remember those?) netted several various pieces of brass and copper tubing. Thanks Carl!

The next morning, a trip to my favorite neighborhood hardware store (remember those?) netted several various pieces of brass and copper tubing. Thanks Carl!

Cut and faced a 2.25" section of the 1/8" diam. copper.

Cut and faced a 2.25" section of the 1/8" diam. copper.

Started to bell one end with a 30 degree point.

Started to bell one end with a 30 degree point.

Bench block held the tube. A small steel rectangle under the block allowed me to hammer a wider point (60 degree) into the end.

Bench block held the tube. A small steel rectangle under the block allowed me to hammer a wider point (60 degree) into the end.

Then, a couple strategic taps with the hammer, one end was finished.

Then, a couple strategic taps with the hammer, one end was finished.

Cut the bad piece in half. It's the only way to remove the nuts and washer.

Cut the bad piece in half. It's the only way to remove the nuts and washer.

Installed on the single-flared-end tube.

Installed on the single-flared-end tube.

Then repeated the flaring step. Not having any 30 year old Crosman "gland seals" handy, I opted for o-rings. I think that's an #A007 on the left and #A006 on the right.

Then repeated the flaring step. Not having any 30 year old Crosman "gland seals" handy, I opted for o-rings. I think that's an #A007 on the left and #A006 on the right.

Though there wasn't one there originally, it looks like the valve-end nut is cut for an o-ring at the end of the thread. I added an #A011. It sure won't hurt.

Though there wasn't one there originally, it looks like the valve-end nut is cut for an o-ring at the end of the thread. I added an #A011. It sure won't hurt.

Test fitting proved my eyeball method of sizing the copper tube length was a bit shy of the mark.

Test fitting proved my eyeball method of sizing the copper tube length was a bit shy of the mark.

So, I cut the short tube in half, removed the pieces and made another. Why do it once when you can do it repeatedly until it's right? Anyhow, reassembled the gun, gassed it up and it leaked CO2 even faster than the first time. The leak was at the exact same spot.

So, I cut the short tube in half, removed the pieces and made another. Why do it once when you can do it repeatedly until it's right? Anyhow, reassembled the gun, gassed it up and it leaked CO2 even faster than the first time. The leak was at the exact same spot.

A bit of cursing and a night's sleep later, I replaced that #A006 o-ring with a smaller #A005 then put another one between the small washer and the nut.

A bit of cursing and a night's sleep later, I replaced that #A006 o-ring with a smaller #A005 then put another one between the small washer and the nut.

Like so.

Like so.

Reassembled yet again, shot a couple CO2 cartridges through to test and it's gassed up and ready for gift wrap.

Merry Christmas everybody!

Reassembled yet again, shot a couple CO2 cartridges through to test and it's gassed up and ready for gift wrap.

Merry Christmas everybody!

Merry Christmas Derrick and Nick.

ReplyDeleteAll the best.

Dave.

Thanks, Dave and Merry Christmas to you. Hey, do me a favor and don't tell Joe what I got him, will you?

ReplyDeleteawesome sauce!

ReplyDeleteHey there. I was checking out your pics in this blog post and it seems you really know what you're doing, so I thought I'd ask you a question! I happen to have the same gun, but it won't hold the C02. I'm trying to figure out if there's an O ring I'm missing up in the piercing assembly. Any thoughts? Thanks in advance!

ReplyDeleteHi! Your blog looks very helpful, but unlike you, I am a mechanical idiot! Please contact me at rmoore1014@aol.com re a Crosman 38C that I just inherited from my uncle.

ReplyDeleteThanks!

Robert Moore

Can u use a 357 crosman cartage seal on 38t with out changing the pin.

ReplyDelete