I bought:

250 Gamo .177 Round Balls. (lead)

500 RWS .177 Hobby

500 RWS .177 Meisterkugeln Rifle

500 RWS .177 Meisterkugeln Pistol

1250 Crosman .177 Premier Light

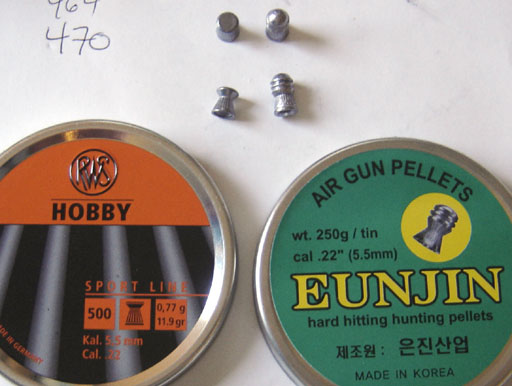

125 Eun Jin .22 Domed

300 JSB .22 Diabolo Jumbo Match

500 RWS .22 Hobby

So 3925 pellets for $71.89 with Pyramyd's buy 3 get one free, and a 10% off discount code.

That's an average of 1.83 cents a pellet, or 54.6 pellets to the dollar.

The Gamo balls were to see if they perform well in some of the CO2 bb pistols I have. I can state that they do not function well in my Crosman 451. Then again BB's don't either...it's a real beater.

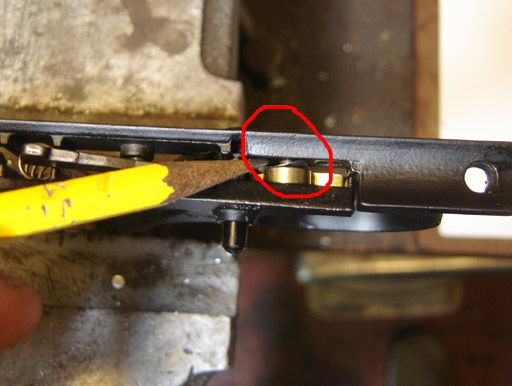

The .22 JSB and .22 Hobby were as a replacement for .22 Crosman wadcutters in my Crosman 400 rifle. For some reason you can't find the Crosman .22 wadcutters anymore. The JSB's jammed in the repeating mechanism, but the RWS Hobbys feed better than the Crosmans did.

I'll shoot the JSBs in my other .22 pellet guns.

The Meisterkugelns are for my "match" guns, should I ever relax enough to do more 10M shooting.

The EunJin's are basically for fun, and as part of my general embrace of Korean culture. They are extremely heavy and large pellets intended for hunting. Not that I hunt, but you never know.

I got out the Chronograph and the Eunjins and Hobbys.

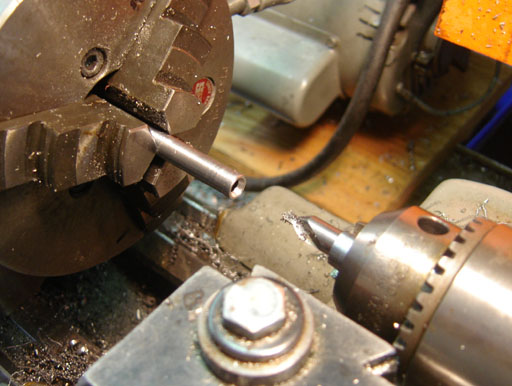

The Eunjins are long pellets!

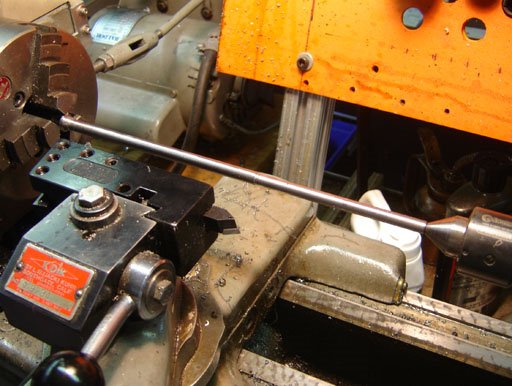

I shot both types through my Benjamin 342.

I only did 3 shots of each type, at 8 pumps.

The Hobbys at 11.9 grains, averaged 654 fps. for 11.3 ft/lbs of energy

The Eunjins at 28.4 grains, averaged 467 fps. for 13.76 ft/lb of energy

It's worth noting that the Original (Diana) 45 that I wrote about earlier averaged 840 fps w/ 7.9 grain pellets for 12.38 ft/lbs. So probably an easier gun to shoot should I need to dispatch a watermelon.

Oh, and here's a post about the Original 45 that I missed before I wrote about it.