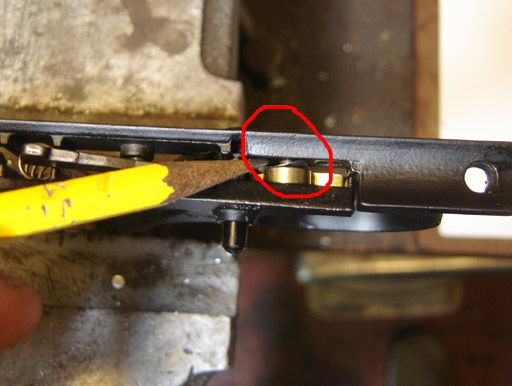

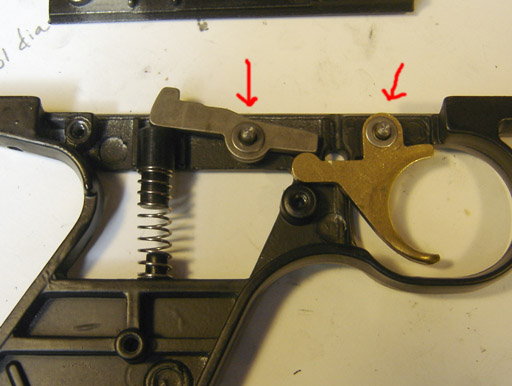

The slot both the sear and trigger ride in is rather wide, so they use a spring washer to keep the trigger straight.

The poor sear gets no such spring and can wobble and wiggle all it wants.

Looks simple from outside...

And it is. That round thing at the upper corner is a magnet I use to hold all the little parts to keep them from getting lost.

The trigger and sear derive their force from the same spring. It's rather hefty and the end just pushes against the edge of the sear.

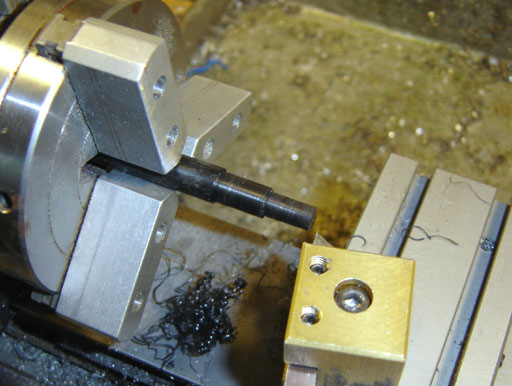

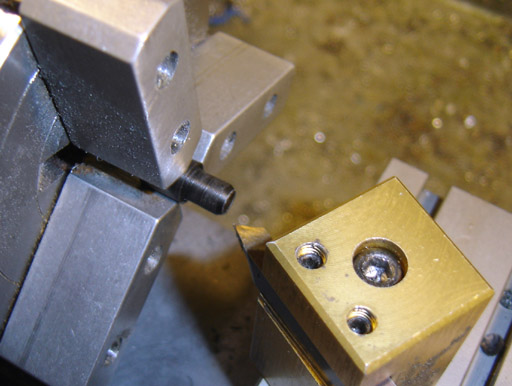

I turned down some delrin to make a spring guide/bearing for the sear.

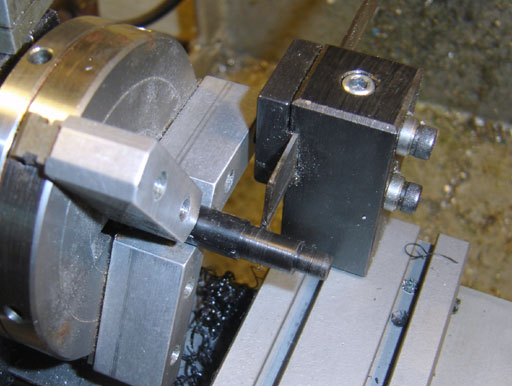

Parted it off.

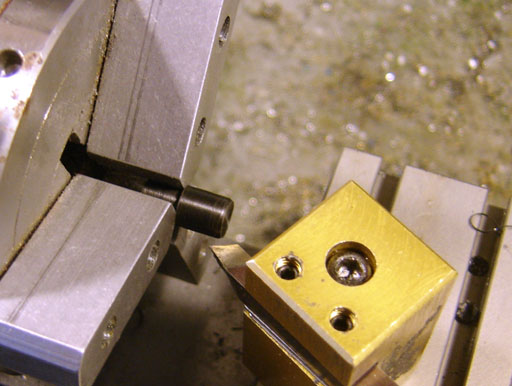

I chamfered the edge and then filed it to a gentle radius.

I installed a shorter, somewhat lighter spring from my cache of random springs.

To solve the wobble of the sear and trigger I used thin washers on either side to take up any play. I was going to make some but found perfect stock ones in my drawer of tiny washers.

I found the end of the guide inside the spring dragged a little, so it got a quick chamfer as well.

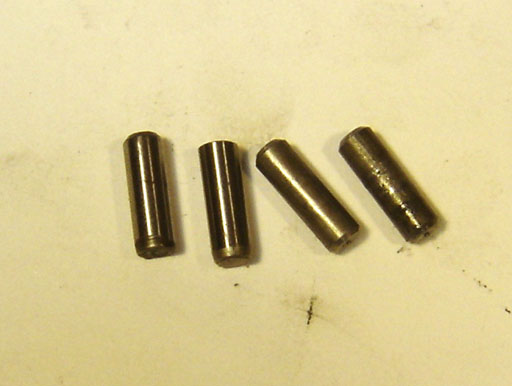

Finally I replaced the undersized and soft Crosman pins (R) with dowel pins (L). I lubed everything and put it back together. The trigger is now somewhat lighter and less "clicky" if that makes sense. I cocked the gun and did the standard drop/hit/wiggle/smack test to make sure the sear still would stay engaged. It did. So one more step on the road is finished.

Good news. Did the same to my 2240, and polished all contact points w/1000 grit wet and dry. Just bought a 1377, and will do the same, and fill the grips with epoxy.

ReplyDelete