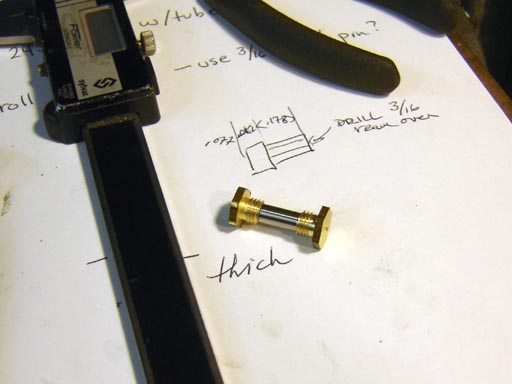

This is what I came up with:

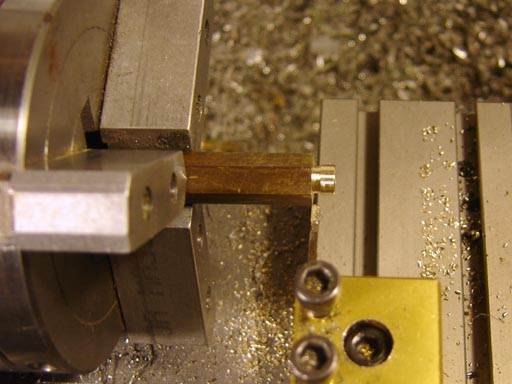

I had some 3/8" hexagonal brass which seemed like the right material for the retainer screws.

After turning down to 1/4", I cut a relief groove.

I then reamed it .001" over 3/16"

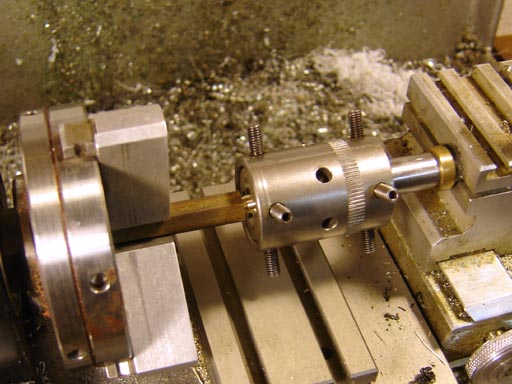

I used the die holder to make 1/4"-28 threads.

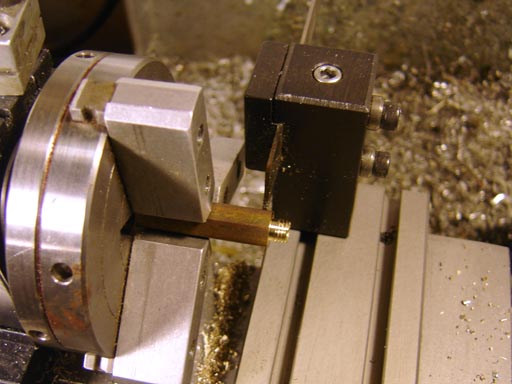

And parted it off the bar.

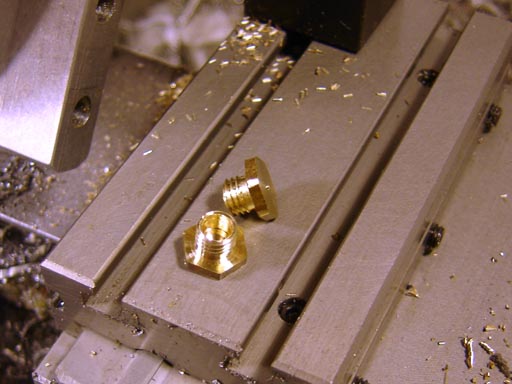

Two retaining screws.

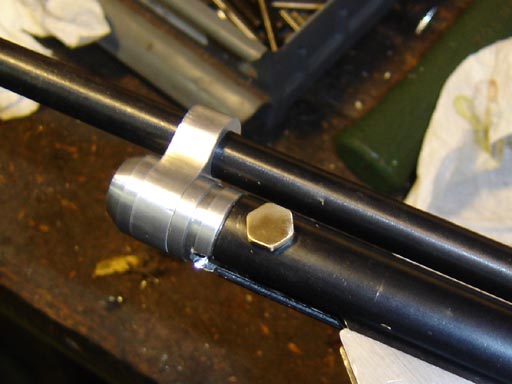

This is what the assembly looks like.

Drilling the pivot hole in the tube out to 1/4" with a Unibit.

A Cogsdill Burr-Off tool, also known as a "clothes pin" tool.

The tool cuts both back and front and springs to fit into holes. It is very handy for deburring the inside of tubes. As you push it in it deburrs the outside of the hole, and as you withdraw it, the inside.

I drilled and tapped the pump arm plug 1/4"-28.

The finished retaining screws installed. I'll polish them up, although I'm not entirely convinced this will be the final design.

My main aesthetic criticism is that the screw stands proud of the tube, only making contact along the tangent. So I may make two slightly longer ones and make washers with a radius to match the pump tube on one side. This would be stronger, and look a bit better. However it will add width to the assembly and I'm not sure if that will look good either...

We'll see.

No comments:

Post a Comment