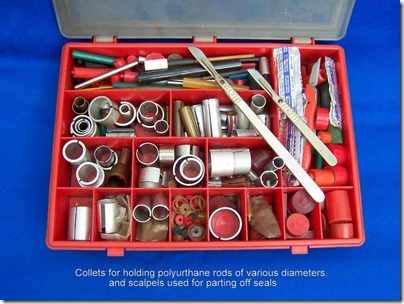

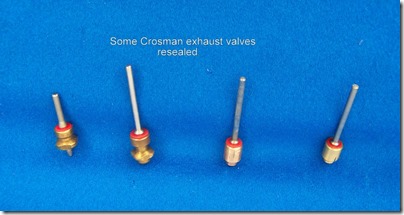

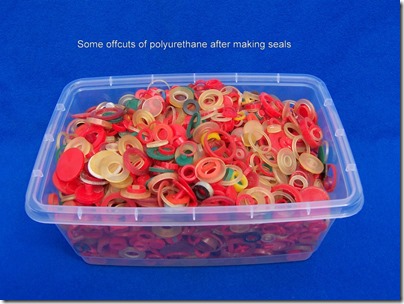

“I don't know if you have heard of me, my name is Lawrie Amatruda, I am in England UK, I read your great Blogs a lot, I hope you don't mind if I share with you my simple way of making flat section polyurethane seals, I am not an engineer, I'm getting to an age where I would like to pass on any helpful knowledge that I have to aid other DIY airgun enthusiasts to resurrect their old guns , I worked out this method some years ago after not very successfully trying to machine them on my lathe, I do lots of resealing of vintage and antique Co2 and pneumatic airguns for guys here, I hope the pictures are self explanatory.”

“…I believe that obviously from all the information you are giving the collectors around the world the knowledge to restore these older airguns for the next generation, the chance to do the same to their treasured collectables, after all we are only looking after them for future collectors to enjoy. Thank you for referring others to me here in the UK, although I am slowing down a bit now, because of my age, so I am fairly selective with the work I take on, mostly the vintage and antique Co2 and pneumatic airguns”.

Thanks so much for this hard-won knowledge Lawrie!

Much appreciated!

ReplyDeleteSome of us amateur airgunsmiths

need all the help we can get!

Now all we need to to know is how

best to make those hollow cutters ;)

Cheers

Brassbanjo

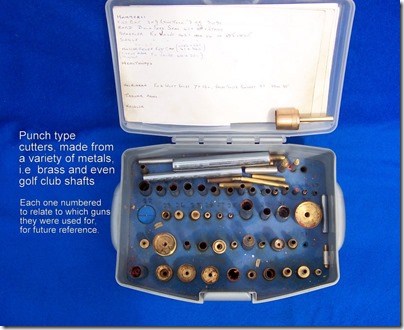

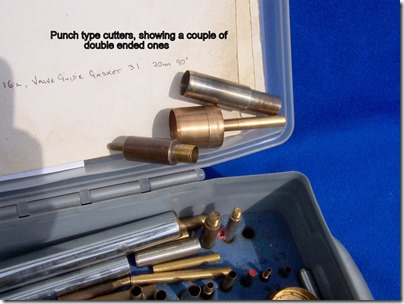

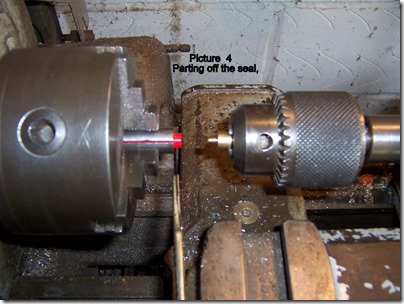

Hi Brassbanjo, I make the cutters on my lathe from a variety of metals, they just need to be to be thin walled and reasonably sharp, as you can see in the first two pictures they are very simple tools, once you have made a cutter to the size required, you can start the sharpening by putting the cutter in the chuck, and with a fine file to begin with, and finish with a fine diamond hone, alternatively you can use wet and dry abrasive paper of varying coarseness, finishing with a very fine one, when using this method I back the paper with a strip of metal or wood, I hope this explains it. Lawrie.

ReplyDeleteThanks so much for the info, I had a couple of pretty old E9a pistols that needed seals, now I know how to make them.

ReplyDeleteAny thoughts on tapered seals, like the ones on spring pistons?

David, I'm afraid I don't do much work on springers but the ones I have done, have mainly leather washers which have much published information on how to make them, I haven't looked in detail but you will probably find some information here on Nick's blog. Lawrie

ReplyDeleteHi Lawrie

ReplyDeleteDo you still service/repair the crossman 600. I have recently acquired an early model that only goes full auto. I would be ever so grateful if you could service this. My email is pip.swarb@gmail.com and my mobile is 07403345243. Many thanks if you can help.

regards

Phillip

Lawrie,

ReplyDeleteI have an early LP3 that needs an exhaust valve rebuild. Is this something you could help with? The gun is mint apart from this fault. I can be contacted on mobiasstrip at yahoo.co.uk

Hoping you still read old threads :-)

Steve

Lawrie,

ReplyDeleteI have an early LP3 that needs an exhaust valve rebuild. Is this something you could help with? The gun is mint apart from this fault. I can be contacted on mobiasstrip at yahoo.co.uk

Hoping you still read old threads :-)

Steve

Hi, have you find any solutions for your problem?, i have the same problem and looking for same parts.

ReplyDeleteLeif N

Lawrie Says:

ReplyDelete"Leif.

I presume you are referring to the LP3, if so I don't supply parts to reseal these, because I have to customize both the exhaust valve and piston head to make them work, this involves me having the gun to work on, if you are outside of England, UK, I am unable to take this work on because of problems with our postal service, which has made it very difficult to send or receive air guns, I can E-mail pictures to you how I do the work if it would be helpful.

Regards, Lawrie"

Keep up the good work,

Kind regards, Lawrie

Hi....I have a perfect Hammerli Master in it's box, but it won't hold CO2. I have unscrewed the aluminium valve cap inside the cylinder....where the nozzle of the CO2 bottle sits...but how does one get this out as it's not a loose fit...although it is free to turn and is unscrewed? Can I send it to someone? Anywhere in UK and Europe would be fine? I heard Lawrie Amatruda is a person how makes seals for these, but can he fix these also? I do hope I can get it working as it is a beautiful pistol. I have a second that works...a later model, but it doesn't have original grips. Thanks and hope to hear from someone. My email is

ReplyDeletesimonspain63@gmail.com

Best to all, Simon

Hi Lawrie,

ReplyDeleteI too have an LP-3 that needs to have it's seals replaced. I am in the USA, but I wondered if I could travel with this on a flight to the UK, with the barrel assembly and grips removed. I owned an LP-2 many years ago, which was lost in various moves, so I was very happy to find this rare LP-3.

Or, if I removed the barrel assembly, could I mail it to you in the UK?

Anyway, all the threads I have seen, say you are THE LP-3 expert. Let me know what receiver parts you would need to replace the exhaust valve and piston head parts.

Contact me at

320pilotfairpoint.net

Cheers,

Ray

just a correction to my e-mail address above, for Lawrie Amatruda

ReplyDeletemy e-mail is 320pilot@fairpoint.net

the should be removed in the e-mail address.

thanks, Ray

ps. if anyone has a current e-mail for Lawrie, could you send me that so I can contact Lawrie directly.