Had a piece of knurled stainless steel. I think Nick set it in a care package a couple years ago. Drilled it out with a 5/16" bit. A piece of black plastic is behind it as a backer.

Drilled a hole in the bottom of the end cap with a #29 bit.

Tapped M5 x 0.8mm. Since it's going on a metric threaded gun...

Flipped the cap and took a clean up pass.

With a small boring bar, I cut a recess in the face for the knurled stainless disc.

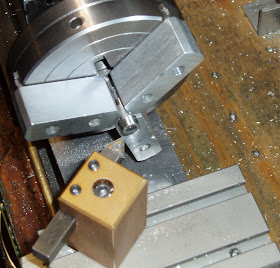

Faced off a piece of 0.250" brass rod.

Spotted--

--then drilled a small hole in the center. I think I used a 3mm bit.

Turned the end of an M5 stainless bolt down to--hmmm--about 3mm.

Flipped the bolt and turned the head down to 0.315"--a couple thousandths over the 5/16" hole drilled through the piece of knurled stainless. I seem to be missing a pic. I pressed the ring and bolt together with some Loctite 680 and let it set up for 12 or so hours. Should be permanent.

Found the bottom of the bore inside the cap and drilled a gas vent hole. The hole cuts a half-round groove in the bottom.

Finished the cap in black. There's the press-fit ring and bolt. The brass tip was cut to size. It's a running fit (rotates freely on the end of the bolt).

Assembled. The idea is that turning the knurled ring should depress the pin in the end of the Aeron bulk-fill adapter and vent the gun. There have been a few times when it would have been advantageous if the gun could be emptied in a couple seconds rather than having to shoot the gun dry.

Getting a bit long. Ah well, it can go into the tool bin if I change my mind.

More soon.

Re: "Getting a bit long." I agree aesthetically it's a bit too much, but really what can you do? Form follows function, right?

ReplyDelete