I decided to try making a replacement piston seal that uses an o-ring for the Manu-Arm pistol.

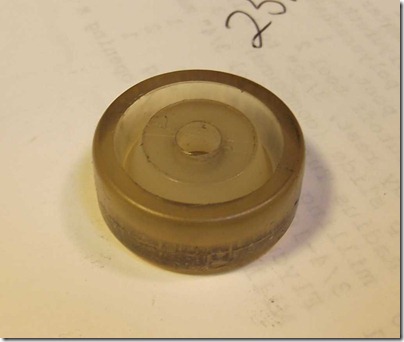

The Seal seems to be almost exactly 25mm.

The underside of the seal.

The screw. It has a 90 degree head…

The piston face.

Drilling some delrin. I ended up using a #4 drill which was the closest I had to the 5.25mm shank of the screw. I turned the body .976”, later ones I turned to .984”. Greater diameter leads to more o-ring support.

Countersinking. The only 90 deg countersink I had was too small…

So I set a boring bar to 90 degrees and plunged in to make the countersink. After this I found a 90 degree spotting drill that was perfect, used it on the rest of the piston seals.

Grooving for an o-ring. I was aiming for about .005” over 5mm with the o-ring installed. But I only had a 116 o-ring and it lost diameter when stretched. Later pistons seals used #118 o-rings.

It shot about 360fps, which was slower than the 426 I got with the original seal. So as I mention above I made some more seals using 118 o-rings, and played with diameters and groove depths. Current seal I have installed is getting between 428 and 436 fps, which is slightly better than the stock seal. So the design works fine.

Seals…

You can see the difference in groove width & diameter. The left one is the current successful design. Both have #118 o-rings. At some point I’ll actually follow the procedures Parker recommends and grind a proper tool, etc.

As usual, an outstanding presentation.

ReplyDeleteHave you or anyone else for that matter tried a quad ring instead of an o-ring ? Even though quad rings have more contact area often the fit doesn't need to be quite as tight ending up with a lower friction solution.

ReplyDeleteI would like to buy one from you.

ReplyDeleteHi Nick , i'm Ed , i'm from France and i have a Manuarm rifle that needs a new seal , i work with milling machines and i wanted to ask you if you could give me the exact size and mesures of the seal you made so i could make my own here across the atlantic. cheers

ReplyDeleteI don't have the measurements, but I would say to just make it to suit the rifle compression tube.

ReplyDeleteHey Nick, would you be willing to make one and sell it?

DeleteHi,

ReplyDeleteI just got one of these pistols new in the case. The piston seal has disintegrated. I'm going to replace it with the Vortek 25mm seal. What kind of spacing and over all height did you use on the second o-ring seal you made. Vortek offers -o-ring seals and moly impregnated parachute seals for both 25mm and 26mm like my old Diana leather seal 45 and I'm not sure which to use.