The Walther LG55, acquired in December of last year from the infamous airgunner Volvo, turned out to have two hairline cracks in the wrist, one on each side beginning at the rear of the trigger guard and progressing backward to the grip checkering. Volvo didn't realize that the stock was cracked and he was seriously concerned about his end of the deal. For what it's worth, I think there's an expectation that mechanical things simply need some TLC from time to time. So, this is my end of the deal and I'm content with it.

Anyway, the crack hasn't changed size with over a thousand shots fired, but I wanted to make sure it had stabilized.

I'd like to apologize for the pics right now: I was working outside in mid-afternoon sun, so the light was harsh, and the gun stock is a fairly high gloss... The reflections turned out to be pretty serious and I ditched many of the images. I didn't have time to stop and download images then re-shoot anything or wait for more favorable lighting.

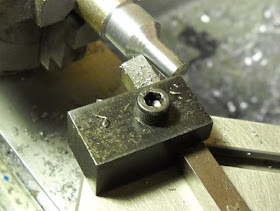

The cracks were extremely small, looking like cracks in the finish. I took about fifteen images to get one that worked. There is an identical crack on the right side. My initial plan was to drill a hole at the rear of the compression tube channel and add a screw to draw up the grip and reinforce the area. With the action removed, that was easier said than done. The inletting fell well short of the area where the screw needed to go. Adding the screw would mean pocketing the rear of the inletting, removing quite a bit of wood in the process. I felt that would have done more potential harm than good. So, plan B.

Titebond cyanoacrylate. Thin. Seems thinner than water. It's made to wick into very tiny places. Hopefully places like cracks in old Walther stocks.

I coated the inside of the inletting of the trigger guard at the rear. Then ran a bead along each crack, one side at a time. Flexed the stock back and forth attempting to open the cracks to allow them to absorb more glue.

Now, to remove the excess dried glue from the surface of the stock. Started with 1500 grit wet/dry paper. Just want to sand the glue line level with the stock finish.

Followed by some Mother's Mag Polish to blend the edges.

Still have a slight glue line. A bit more sanding. Tried very hard to not burn through the stock finish.

Glue line is gone.

I'll give it a wipe with Tru-Oil and let it dry for a day.

Rubbed out the Tru-Oil with a bit of rottenstone.

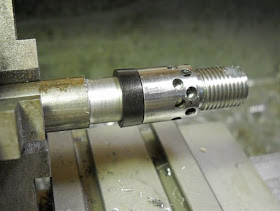

I can't find evidence of the cracks or the repair. I'll inspect the stock after every shooting session, but I think it'll be OK.

The sixty year-old Walther Luftgewehr 55 lives to shoot another day.