.25" brass tubing this time.

Coring the hole.

I cut the cup end off with a knife.

Much better than trimming by hand.

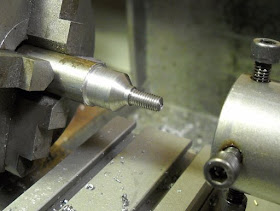

Turning a shank and the taper.

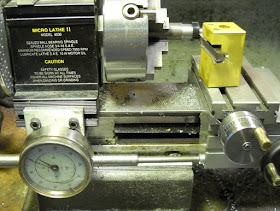

Checking for depth.

Shoulder, threads, check!

Looks like it works.

Cutoff.

Cleaning up the face.

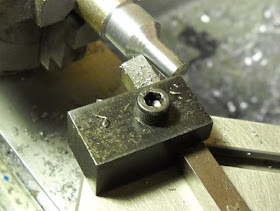

Slotting the head for a screwdriver, .032" wide and deep.

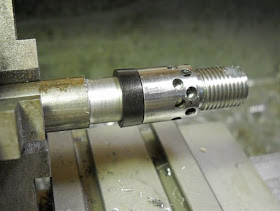

The piston head, all done.

It stopped raining long enough to run a few shots over the chronograph. With 10 pumps, CPL 7.9 gr. pellets, I got a very consistent 757 fps (+/- 3fps). That's a 17 fps improvement over the o-ring! I would have been happy had it been a bit slower. I'll be trying this mod in all the Crosman pumpers from here on out.

It took awhile but finally I found a website/blog for a few air pistols my father in law passed on to me (both without a user manual). Slavia ZVP and Crosman 1377. Of special interest to me was the ZVP since it wasn't firing. Your photos and comments helped me with the teardown and cleanup of this particulr air pistol. Works like a charm now after a few a few hours of some TLC.

ReplyDeleteOne question about the Crosman 1377. Sometimes when inserting a .177 it goes in sideways and gets jammed. Any suggestions or hints to prevent this (aside from being very careful).