When I bought the HW35E a month or so back, I also found this British made muzzle brake/moderator. Came in a plain cardboard box with a "made in England" sticker. The only other markings were handwritten: "for HW35 2-piece unit adapter and moderator for use with open sights all aluminum-unfinished"

Not much to go on.

I assumed the end cap was threaded to the main tube. Nope. It was juts a bad press fit. Inside, I found 2 coil springs and an aluminum cone shaped spacer. The piece on the far right is held onto the gun via the front sight and the brake threads into it. Please leave a comment at the end of the blog post if you know who made this thing.

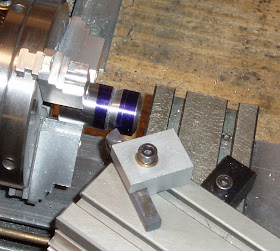

Since the end cap didn't press fit all the way home--and since that's a lousy way to retain a part on a spring piston rifle, I shaved the OD of the cap down in the Taig.

Holding the piece was tricky--as was finding a knife that allowed enough clearance. A tiny homemade boring bar ground from a 1/4" blank tool bit just fit.

Now the cap will press in flush.

The body is marred in several spots. How many years of rattling around in various drawers? I'd think 20 to 25.

A well-greased dead center to hold the free end of the brake and a deft(ha!) touch on the carriage.

Many light passes later removed all the dings.

Another view.

A scotchbrite pad held against the surface gave a nice matte finish.

Did the same to the "adapter" piece.

Again, just another view.

Wasn't thrilled with the brake cap being simply press fit. If I do install the springs, they bear directly on the cap and will force it out of position. With the cap gingerly held in the 3-jaw, I cut a groove almost at the shoulder with a small parting tool.

Yet another view

And added a small, thin o-ring.

Size--unknown. Just grabbed something from a Plano box full of rings that looked somewhat promising.

With the cap pressed in, I marked 3 holes around the circumference.

And drilled with a #43 (0.0890") bit.

Followed up with a #4-40 tap. Did this 3 times.

The setscrews thread right into the outer wall of the brake as well as into the cap. It's not moving.

The brake wiggles a bit when installed on the HW35. I found an M5 x .8mm set screw to modify. Cut one down with a hacksaw and threaded it into an M5 nut--on left. I think the set screw was originally for a Leapers/Centerpoint scope mount as a recoil stop pin.

Faced the set screw.

And using a 3/32" end mill, drilled a flat bottomed hole.

Then turned down a small piece of delrin (AKA: acetal) to fit. Parted it off and pressed it into the set screw. The delrin protrudes about 0.050"--enough to not mar the barrel.

Drilled the bottom of the adapter with a #20 bit.

And using the chuck as a tap holder, tapped the hole to M5 x .8mm for the set screw.

Installed over the ugliest carpet in the attic I could find.

Interesting design. I'm fascinated with how they thought to mill the brake for the front sight. I can't imagine how many models of bases they'd have to make to fit all the various guns. Didn't bother to install the springs or the aluminum cone. There is absolutely no noise reduction whatsoever. Don't yet know if this is a keeper on the gun. The rifle looks like it could be used for pole vaulting, it's so long.