Figured I'd use a stock Crosman hammer as the model. This is the current hammer, it's got a half-round relief groove to clear the rear breech bolt.

Chopped off a piece of 0.750" diameter drill rod.

OK.

Yep, faced both ends.

Figured I'd start with the bevel on the face of the hammer. Butted the Crosman hammer against the faced end and angled the knife to match the angle. Basically, just used the stock part for my set up. Easy--and no measuring.

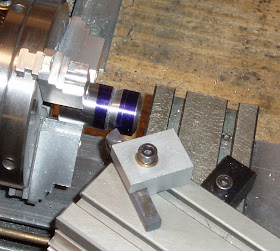

Then turned the same bevel into the work piece.

Measured the OAL of the hammer,

and transferred that to the piece. The layout fluid lets me see the line to cut to.

Faced the workpiece down to the line. It's well within 0.001". More precise than it needs to be. It just smacks the valve after all.

Mine is on the left. Need to drill a hole for the hammer spring.

Spotted and drilled successively larger. Finished at 5/16" diameter. Then (not shown) using a 5/16" center cutting end mill, I cut the bottom of the hole flat for the end of the spring.

More layout fluid. Did some measurements and transferred them to the workpiece.

Some comparison with my SPI angle gauges measured the angle at 25 degrees. The angle is cut with the compound crosslide.

Took some time and repeated comparisons to get the length of the tapers to match. Mine is on the left.

Need to cut a relief groove, notch, whatever to clear the breech bolt (It'd actually just be easier to cut the bolt shorter) and the hammer still needs a hole drilled for the cocking pin.

Next time.

No comments:

Post a Comment