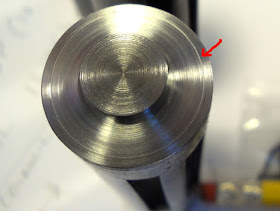

I chucked it in the 3 jaw. You can see the folded over burrs that are keeping the loose head in.

I turned away a couple of thou' at a time. I wanted to remove the minimum.

Then when I had a nice clean ring on the face I started working on the inside rim.

At this point I was able to pop the head out. Those burrs were thick.

The head...

The back side. As you can see it's a rivet of some sort that retained the original seal.

Dialing in the piston in the 4 jaw chuck.

Boring the recess true and clean.

Ready for a head.

The insert roughed out.

Using a form cutter to make the dovetail button. Notice the chatter marks.

Final cutting, chatter removed at very low speed.

You can see the tool I ground. The Diana pistons seem to have a 70 degree dovetail as best I can measure.

Cutting the insert off.

The insert.

Fits!

I soldered it in with soft solder. The new acetylene tank did not catch on fire like the old one did last time. A nice even ring of solder holding the insert in. I cleaned the face up with a very fine pass across the face.

You can see the solder flowed inside.

Using my extremely handy Diana seal tool.

Popping the seal on. Notice I cleaned up the OD near the head as it was a bit scored.

The seal in place. Looks good.

Another shot. I bought the seal from Air Rifle Headquarters. He gets a lot of my money these days.

Now to derust, deburr, clean, reblue the pistol, make breech seal (o-ring) shims, lube and reassemble...then test. Then if it works... fix the cap that screws on the end...all the ones I have are beat up and I should make a threaded arbor so I can reknurl/cut new knurls after truing. fix the stock... fix the windage screw... I'll never run out of projects.

I once attempted to solder and pin a piston head onto a "rolled plate" piston body. Needless to say, the solder broke loose, and the pin bent along with the piston body.

ReplyDeleteThis was on an el-cheapo (Industry brand B3) but I do wonder if the solder you used will be as strong as, or stronger than the "burr" that held the head in previously.

I'm wondering if it will work too! The Diana 5 doesn't have the same forces as a rifle, so I'm guessing it will be fine. If it does break I'll have to either weld it in and retemper the sear, or silver solder/silver braze it in and try to sink the sear so the heat doesn't ruin the temper.

ReplyDeleteLike many of the things I do, it's an experiment...

The IZH 513M I have, which is brutal and has a very strong spring, uses a pin to retain the head.

hey my piston head looks very similar to that (less flat but not good at all) we just hammered it out tonight and got it to pop out mines a later diana model 5 and what is the o ring for (im still getting used to fixing an air gun i normally only work on powder guns)

ReplyDeleteThe o-ring in the breech? It's for sealing the barrel against the compression tube.

ReplyDeleteok thats still in good shape thankfully haha wanted to make sure there wasnt something i was missing thank you

ReplyDeleteHave a Diana 5 pistol. Replaced the piston seal and then tried to reisert the piston, spring and spacer into the cylinder. Cannot seat the assembly. Compression hits hard stop about 1 inch before I can enngage the cap threads. What's stopping the assembly? How do I reassemble without damaging anything?

ReplyDeleteVerify that the piston is bottomed out in the cylinder (stick a pin through the transfer port). Sounds like it's hung up somewhere.

ReplyDeleteThanks, did what you said with the piston on my Diana 5 and it worked.

ReplyDeleteThanks.

Upon reassembly found chamber pressure inadequate for good performance. Disassembled again, installed a new piston seal but can't get the seal/piston into the cylinder without damage to the new seal. How can I get the piston/seal into the cylinder safely and easily without damaging the seal which has a larger diameter (by a bit) than the cylinder? I've tried spring clamps, hose clamps and even tried shrinking the piston & seal combo using liquid nitrogen. Nothing worked. Help please.

AZGULCH

Sometimes you have to size the seal (do a google search for 'seal sizing maccari" or "airgun seal sizing" as there are so many variations in tube diameter, etc. Often it involves rotating the seal and sanding it lightly to remove a few thousandths of material.

ReplyDeleteWell, I just bought new breach seal and shim and a piston seal. My pellets often come out the barrel now but timidly bounce off a softwood round.I am at a loss what to do now to make my Diana 5 work.

ReplyDeleteChris

Seal may be too tight, might have to remove a few thousandths off of the lip diameter. Or it could be too loose. Or the spring could be bad - might need a springier spring.

ReplyDeleteHi just stripping down diana marked on top of barrel original not gecado but exactly the same wooden stock and tapered barrel have perfect piston if you need info on, a very well made gun thanks for your blog Trevor, my email trevorjohnwendel@gmail.com

ReplyDelete