The end cap was beat up so I decided to try cleaning it up.

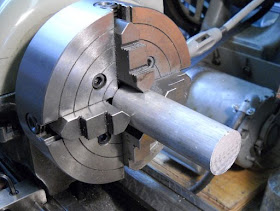

First I chucked up some aluminum.

I turned some steps, only the front one matters although the other ones will be used to true it in the chuck if I need to use it again.

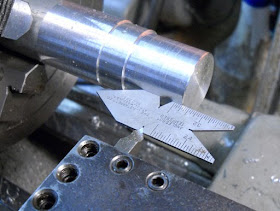

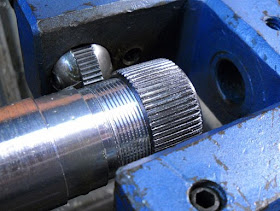

Setting the threading tool.

Interestingly enough, the thread seems to be 24 tpi, not metric.

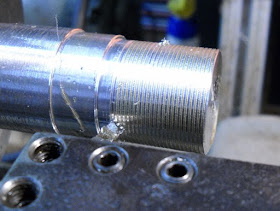

Cap screws on.

I filed the radius and faced the front.

You can see it's a trifle messed up.

I removed a little bit at a time.

Until it was clean.

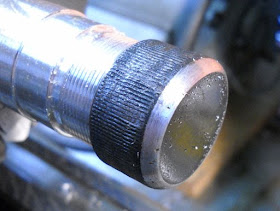

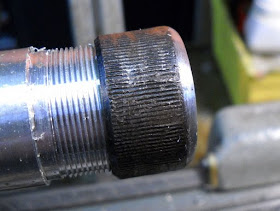

I then knurled it. I had to adjust the rollers again to get a full depth knurl. If I do it again I'll order slightly finer knurls as these were pretty coarse.

Not bad?

A little abrasive brushing removed the burs and such.

Night and day on the knurling. I was thinking you'd need to use a thread restoring or riffling file to clean up the knurls, but those look great. Let us know what you blue it with.

ReplyDeletea rookie question, it looks like you cut the threads with the compound at 90 to the work. I say compound, i can't tell, maybe just a cross slide.

ReplyDeletebut if compound, why is it set at 90, and not the approx 1/2 of the thread angle, ie 29 - 30 degrees?

I'm not arguing with success, you realise :)

alistair

It's hard to tell from the pics but the compound was set at 30. But Sometimes I will just plunge in with the cross slide rather than feed at an angle with the compound on a small thread like that.

ReplyDelete