I pulled the cam rod out of the other 600, the new ring wouldn't slide all the way. Again a corner clearance issue. Just wanted to check. Obviously all it needs is the corners relieved in the helix. Better too tight than too loose in my book. But I'm not using this rod in this 600, because it's in the other one...

So I found some 3/16" square and radiused the edges to fit the new ring.

Cut to length and the corners radiused to fit the new ring along the length of it.

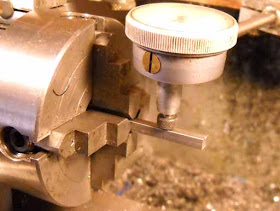

I chucked up a 3/16" dowel pin in the 4 jaw and got it true. This saves time when chucking square stock.

Truing up square stock in a 4 jaw is difficult. You have to wiggle the chuck to find the minimum reading at each jaw before adjusting. A little time consuming.

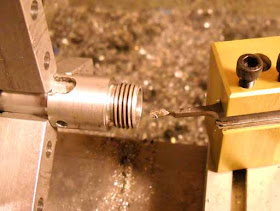

The round section turned on the rod.

I put the good cam rod in the mill vise and set the stop. I lined up a ball endmill with the divot.

Milling a round pocket for the feed arm set screw.

I put the rod in a vise and twisted it with the adjustable wrench held right where the helix ends. Very easy. I was a bit nervous doing this by eye rather than taking 100 measurements, etc. But I doubt the tolerances are that extreme. It has a little bit of play. If I were to do it again I'd make the rod out of stock slightly larger than 3/16" maybe .190" I'd probably also spot for the setscrew divot by holding the feed arm in alignment with the magazine.

The gas leak was no doubt due to the extremely wide valve seat.

I ground up a skinny little toolbit and fed it in carefully to trim the outside diameter of the seat.

The ring is thinner so more force holding it shut.

The last thing I did was polish the lead of the feed arm. I used a cratex bullet and got it smooth.

So...it works! I doesn't go full auto and doesn't leak. It feeds fine with 8 pellets in the mag but with 10 sometimes it jams and sometimes it doesn't. I think that it's due to the overall slop (the feed arm was really scarred up) where the pellets go into the feed arm, leading them to cock. If the magazine spring had slightly less force it would probably be more reliable. I'll see how it performs over time.

Now this is not a pistol I have a lot of confidence in. The wear on the sear parts means I'll always have to keep an eye on it. It also makes me less likely to buy a 600 without being able to check those parts before purchase as both of the 600's had issues with those parts (broken link on the other one).

No comments:

Post a Comment