I picked up the lower pistol, a later Benjamin 137 (.177 cal) earlier in the year. Unfortunately it works fine. The upper pistol, a pre-1952 (according to Fletcher's "The Saint Louis & Benjamin Air Rifle Co.'s") Benjamin 132 was purchased in November and happily doesn't work at all! So I'm going to tear into it.

Just a few comparisons. Besides the use of plastic grips on the 137 and some differences in screws, the sight on the earlier pistol is a one piece brass affair, where the later sight is a steel stamping.

The markings on the breech cap are different.

The 137 has the model info on the right side.

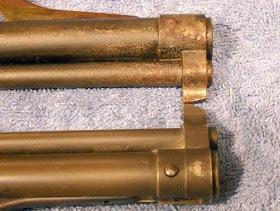

The later pistol's barrel seems to protrude beyond the muzzle plug, where the earlier's is flush. Enough of such mundane matters, on to the fun stuff!

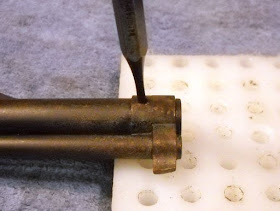

The lever hinge pin lock screw.

Removed.

Punching out the lever hinge pin.

Notice the groove that the screw tip locks into.

I pulled the lever free.

I pulled out the muzzle plug.

A disgusting mess.

I lined up the link coupling pin with the hole to remove it but it wouldn't press out.

Because it's offset...hmmm...

So I used a small diameter pin punch to push it out. A reminder never to force anything.

With that I pulled out the pump plunger assembly.

With the worst wiped off...It doesn't look too bad.

I could not for the life of me loosen this screw...I'll touch on this later.

I unscrewed the pump rod from the link coupling.

And the felt oiler comes off.

On to part two shortly...