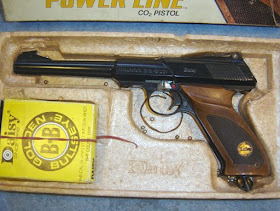

I wanted to post some basic info on the Crosman CO2 guns. I know we get some new shooters who are often unfamiliar with our lingo. We often say 22XX or 17XX to denote calibers of Crosman 2240, 2250 and 2260 CO2 guns. The 22 or 17 refer to the caliber--so it's possible to even have a 20XX or a 25XX... The "XX" means the information still applies regardless of whether you have a pistol (the 40) carbine (50) or the rifle (60). Technically, there are also the Crosman Custom Shop guns--like the 2300--so this can get confusing as to just what the heck we're talking about if you're not a dyed-in-the-wool Crosman freak.

Crosman built their line of 2240, 1740, 2250, 1750, 1760 and 2260 as a modular system. (ED: as is the 1377 pneumatic pistol) Most all of the parts can be swapped back and forth quite easily between guns to get the features desired. For instance, it's possible to convert a 2240 basic pistol into a short carbine with the addition of the shoulder stock from the 2250. You can also convert to 0.177" cal with just a new barrel and bolt.

The most common upgrades to the guns are the steel breech addition as well as a trigger job. I wanted to document both so we had a reference. The steel breech upgrade adds both a dovetail mount for a scope, as well as vastly increased barrel support. The procedure for its installation is also the same if you want to change to a different caliber.

Remember, all the procedures are essentially the same. I built this gun up from parts so I may use an allen wrench where you may need a flat head. My barrel won't be the same length as your barrel... You'll get the gist.

Obviously, unload the gun. Remove the Co2 from the gun, too--just in case. By the way, all the threads are Imperial. No metric spoken here today.

Loosen the setscrews top and bottom on the barrel band.

Slide it off the lower gas tube.

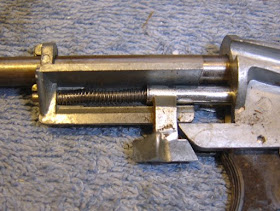

Pull the bolt back and expose the head of the nefarious 4-48 screw.

Using a 0.05" allen wrench remove the little bolt.

Remove the rear breech bolt (it's an 8-32) that threads into the rear cap on the gas tube.

Voila. The breech falls right off. Take note of the small cylindrical rubber ring. This is the transfer port o-ring.

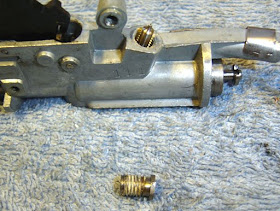

The small steel silver cylinder is the transfer port. The long end fits into the bottom of the barrel where it brings in the CO2 behind the pellet. The short end fits flush against the top of the CO2 valve surrounded by the o-ring.

Here's a Crosman steel breech assembly. The barrel slides into the front where it's held by a setscrew.

Said setscrew. Loosen it a few turns out before installing the barrel.

When you install the barrel into the breech, make sure to align the transfer port holes. This is maybe where I mention that both the Crosman .177 and the .22 cal barrels have an OD of 7/16", so the breech is exactly the same for either caliber, it's the bolt that comes with the breech that will be different.

Like this.

I put the transfer port o-ring into the hole on the gas tube. Set it right on top of the brass CO2 valve assembly.

Transfer port goes on next.

Separate the handle from the bolt if they're assembled. Install the bolt into the channel in the breech. Thread the bolt handle back in. The bolt needs to be the correct one correct for the given barrel's caliber. A bolt for a .22 cal barrel will not seal properly on the .177 barrel.

The pin sticking up at the rear is attached to the hammer. It must be behind the rear of the bolt to function correctly.

Line it all up and reinstall that 4-48 bolt. Gently snug it.

Place the breech cap into place (this silver one isn't stock. I turned this one a week or two ago on the lathe) and thread the 8-32 rear breech bolt home.

Check that 4-48 bolt inside the breech again and make sure it's still snug. Reinstall the barrel band and snug its top and bottom setscrews.

Another view. It occurred to me that this info is also applicable to the Crosman Discovery as that PCP rifle utilizes much of the model 2260-- including the steel breech upgrade kit. If you fancy changing calibers, just follow the above steps and sub in the new barrel and correct bolt.

No barrel band on this one. If the barrel isn't overly long or heavy (shrouded?), you can get by without the band. The barrel now is supported by both the ID of the breech as well as the setscrew. You cannot do this on the stock plastic breach because there's insufficient bearing surface between the barrel and the breech as well as no setscrew support.

Oh, and now the gun has .22 dovetails. Optics here we come.

Coming soon: A basic Crosman trigger job that will take the stock trigger below 2 lbs. and remove the grind.