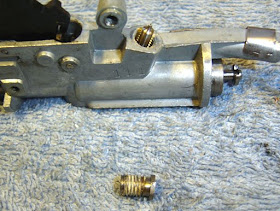

Unscrewing the piercing nut.

The nut has threadlocker or sealant on it.

Punching out the trigger pivot pin.

It has a raised area so can only go in or out one way.

Punching out the pin that retains the BB shuttle.

It's knurled as well.

The shuttle orientation.

I pushed (not hammered) it out.

Some old grease on the shuttle...

The piercing pin.

There's a seal for the body of the pin down there, hardened and sticking to the wall. It'll have to come out if (emphasis on "if") I ever reseal it.

I carelessly unscrewed the valve. Grant Stace did a much better job.

This is what comes out at first.

Then these nested seals.

They have mating convex and concave features.

So that's it, all taken down. I doubt I'll ever work up the enthusiasm to try and get it working but if I do I have a record. For now it goes into a ziplock bag.

Hey, I have a Daisy CO2 200 Pistol that was my dads when he was a kid.

ReplyDeleteAfter his father (my grandfather) recently passed away, we found the pistol in some of his stuff.. It has been stored away for at least 20-25 years, and when I got it, the gun leaked like crazy as soon as I punctured a fresh CO2 cartridge. It would de-pressurize in about 30 seconds.

I disassembled it as far as I could, then found your instructions and used then to disassemble the valve. Most of the seals inside of the gun are made from hard plastics like nylon that really wouldn't wear out easily or harden and crack, testament to the to "no o-ring" design, so I wasn't quite sure why it leaked.

Anyway, I lubed the "seals" up good with some lightweight silicon based grease, and then as I was re-assembling, my eye caught that "0-ring" like seal around the threaded portion of the valve that you twist into the body of the gun (with pliers) to hold all the valve parts inside. It looked dry, kinda cracked, and hard, so I lubed it up with silicon grease, and then wrapped some Teflon tape around the threads in front of that seal, making sure not to let any tape hang over and interfere with the internal workings of the valve. When I put it back together, I attached the lower portion of the gun and installed a C02 Cartridge. It still leaked slightly from the threaded portion, but after tightening the threaded "valve retainer" another 1/2 turn, it stopped! I hadn't tightened it enough. Now the gun holds air and I'm very pleased! Its an awesome pistol, quite powerful and extremely accurate! The trigger pull is extremely light, and the semi-auto no cocking design is really sweet! I got about 170 rounds through it on one C02 cartridge and half of those came after the gun sat for about 7 hours! (I went to school!)

Anyway, I just wanted to share this because its so easy to do, and I know there are lots of people who have these guns that leak! (They're known leakers) I have 5 different CO2 pistols, and this 40 year old design is now my favorite one because of its power, ease of use, and accuracy!

Hey there , I’m happy to say that I did pretty much everything you mentioned and after fooling around with it for days. And having the spring and cap escape on me a couple of times, the thing now works great! The silicone tape on the threads if the co2 piercer was the magic.

DeleteThat's great news! I sent this one to Derrick and he found the same thing once he modified the piercing pin to seal better.

ReplyDeleteAh okay sweet! I have a different type of piercing pin on my gun, its a one piece design where the piercing bit is actually part of the threaded "nut" that screws into the gun. It looks like it would be far less likely to leak. My piercing pin was originally clogged up, but I unscrewed it, cleaned it out (with carburetor cleaner lol!) and then screwed it back in, didn't even have to use Teflon tape and it seals fine. Have you gotten yours back yet? I only got mine working last night, and I've already put about 600 rounds through it today lol!

ReplyDeleteActually Derrick's keeping that one, but he's been enjoying it and found he can shoot lead ball.

ReplyDeleteI have another 200 I picked up cheap a little while agao that I'll get around to trying to fix.

I lost the spring for the shuttle have tried 2 replacements that seem to be correct. when I load co2 cart pull the trigger once and tha shuttle stays up when I take co2 cart out the shuttle comes down and trigger works normal anyone have any suggestions

ReplyDeleteIn response to anonymous's comment about the shuttle spring, it sounds like maybe its not strong enough. Make sure the shuttle moves freely, and try to find a stiffer spring. If its not stiff enough, it won't return down like its supposed to!

ReplyDeleteI have a Daisy CO2 Pistol and it leaks as well. I have the one with a one piece design where the piercing bit is actually part of the threaded "nut" that screws into the gun.

ReplyDeleteMine leaks imediately when you screw in the co2 cartridge.

I see that Felice sent it to Derrick to fix.

How did that work?

I would like to get mine fixed as well.

I sent it to Derrick, but for him to keep. Neither of us repairs guns for other people. I'm not sure who does work on the Daisys.

ReplyDeleteBruce,

ReplyDeleteI made a new nut that threads into the valve and surrounds the piercing pin. The nut has a flange with a recess around the pin. An o-ring fits into this depression with the piercing pin in the center. The sides support the o-ring from blowing out and leaking. The pin pierces the cartridge and the o-ring seals against leaks.

I'm pretty sure that you can substitute the nut and seal from a Daisy 1200. I'm not positive, but I think it'll work it you can't make a new nut yourself. I have seen a Daisy CO2 200 that had a seal just like that. Not sure if it was a production run change from Daisy or done later.

If I had to make another, I'd consider using a Crosman 2240 valve seal. They're thin and readily available.

I have a Daisy model 300 co2 rifle, and it looks very much like the 200 pistol. It leaks very badly and I might try the tips you all have mentioned. Thanks for your tips.

ReplyDeleteWow, glad to see others still have theirs also. Have mine 40+ years and after digging it out the other day still looks great. They don't make them like this anymore. I'm gonna get some CO2 cartridges this week and see if it still works (as a kid I used to use the plastic adapter and use the cartridges intentended for selzer makers. To lube this I see the oil arrow with the grip off, does that hole on top of the gun get oil also ?

ReplyDeleteI have been having leaking problems with a 200 as well. The tip on the thread tape worked for about 10 shots and then it started leaking again. I have the thing completely disassembled on my desk. I can't figure out what could be going on. I know the piercing group is set and sealed well. Has anyone else had a similar problem?

ReplyDeleteThanks for the good discussion on here. It has been very helpful!

I have the same pistol and did have the leaking when inserting the cartridge. i actually added a small piece of inner tube cut to size and that worked great.

ReplyDeleteNow a new problem after many days of working well it jammed and began losing air. I took it apart again but only got a few shots again. I have old bbs although they look new. I am wondering if they are the problem. I also suspect the trigger but not sure.

Any help would be great. This is a great gun and I've had it since I was a kid.

Two Ton Tommy

Thankx to all for your help in fixing my leak C02 200 pistle all your comments and disassembling stats sure helped. I have the original box and receipt dated April 2nd 1965, $21.00. I am still having great fun with this gun.

ReplyDeleteBruce

Just stumbled across the posting on the Daisy 200. Finally got mine swending BB's down range just fine with a little TLC. I've taken and replaced the old style piercing pin with a 1200 pin, and installed it with 'red' locktite, which solved that problem. Now to solve the major leak around the rear screw-in plug which houses all the valving, it has to be removed with a little psychical force. Holding the cast assembly very gently in a padded vice, or a large friend with padded pliers, grab the 'smooth' shoulder with a small pair of 'vice-grips' (you don't want to slip here) unscrew the plug. The seal, what was left of it, has to be removed, either by pocket knife, very small screw driver, of any like instrument (mine was brittle and flaked off). This plug assy is steel, so don't worry about gouging or scratching it with only hand pressure. Now polish it as best as possible with fine steel wool. Now the trick is to get a o-ring that fits (being streched a little bit) in the recess you just polished. I got a o-ring kit from 'Harbor Freight' that had a perfect size that works just great, and seals perfectly. Now I can pick a cat off the fence with no problem. It's really fun reliving life as it was 40 years ago much to the chagrin of the local cats....Byron

ReplyDeleteGentelmen:

ReplyDeleteNow that I've got my 200 active again, does anybody have any information about leaving it charged. I know that the 1200 body can literally be expanded (ruined) by leaving the cartridge in the gun for an extended length of time.

Great advice. I found my 200 and after 35 years it leaked. Following your advice the gun has been refurbished and is fully operational.

ReplyDeleteThanks

I have a 200 that I bought from a friend when I was 13 yrs old (1963) with a damaged piercing pin that I never replaced--I would like to find one now so that I can replace it and sell the gun in good working order--anyone know who can supply this part?

ReplyDeleteShort and sweet; this blog and comments helped me bring my Daisy 200 back to life.

ReplyDeleteThanks Nick for the excellent breakdown photos! I had my pistol broken down in no time at all. You made it easy.

I soaked and cleaned all the parts and seals in Ronson lighter fluid and replaced the brittle outer nylon(?) valve seal with a #7 rubber O-ring tightened down as far as it would go. I removed and cleaned the piecing needle retaining nut, but I did not remove the needle. I reinstalled the retaining nut with Loctite Thread Locker Blue 242.

Based on a comment here or elsewhere, I let the gun sit overnight. Good karma I suspect.

The rightside hand grip screw also needed a twist of fine wire on its threads to tighten it up a bit better.

The next day I went through two Crosman CO2 cartridges and a lot of BBs. So far I've gone through a dozen cartridges in just under two weeks and there is no sign of any leak yet! Well worth the time and effort!

I bought this pistol when I was in my teens. I'm now 59.

Knowledge is power! Thanks all for sharing yours!

Hi all, I just bought a 200 off gun broker and waiting for it to arrive, but while waiting I was wondering if any of you guys has had any dealings with the Daisy

ReplyDelete100. Is it simular inside as the 200, does it come apart the same way. I've had mine in excess of forty years and it has leaked for at least 35 of those,but when it did work I remember it being very accurate and powerful for a BB pistol.

From Flightsimmer

ReplyDeleteI have a Daisy 200 pistol and have found that the seals are fine but it sometimes leaked when inserting a new CO2 cartridge.

The cause was found to be that the elevator would stick or jam in the up position once in a while so before inserting a new CO2 cartridge I always check to see that it is in the fully down position.

I would like to replace the piercing nut with one with a much better positive seal on the cartridge neck (perhaps as suggested with one from a Daisy model 2240 air pistol).

Also I found that a #6 o-ring from Lowe's fits and seals the rear cap valve and works well.

Once you learn the trick of reassembly it becomes much easier to do.

Mine is still shooting and is in excellent shape.

Flightsimmer

Nick,

ReplyDeleteI am not good with working on small gun parts and my 2 gun smiths will not touch this 200 I picked up this past weekend. If somebody is interested in doing it for pay, I will ship it out to you tomorrow.

I thank you in advance for your consideration. Please email me at nedbruha@cox.net

Bruha

All I can not get the barrel/trigger assembly out of the outside barrel on mine. There is a pin I push down on the top but I think that is hanging on something. Any ideas here??

ReplyDeletei unscrwed the pircing nut and the pin came with it and it will not come out of the nut. it will not move at all in there. dose any one have any solutions?

ReplyDeletemy 200 has been fixed for leaks but now it will double fire at time any ideas

ReplyDeleteThe elevator spring in the top of the gun has gotten weak. Some times you can stretch the just a little and make the work

ReplyDeleteMark, the pin/elevator spring is hanging up on the screws that hold the sight on. Remove those two screws (Daisy manual says only use a dime to turn these screws) hold a small towel over the top of the gun to catch the spring and pin when the mechanisms come out of the barrel. It'll take some jiggling, but it will come out. When reassembling, the pin goes into the spring. Replace the sighting screws, but only tighten enough to make a smooth surface for the elevator spring and pin to pass when reassembling.

ReplyDeleteGood luck!

My dad just gave me his old 200. He said it leaked so I didn't even try a cart, took it apart and the seal on the valve plug literally fell apart. My plug has a 7/16" hex where you guys are grabbing roundness with pliers so I was able to use an open-end wrench. I found an O-ring at the hardware store that fit: 3/8" i.d. 1/2" o.d. 1/16" thick. put some lithium grease on it to keep it from drying, added teflon tape to the threads, oiled everything else with fishing reel oil and it works great! No leaks!

ReplyDeleteThanks for posting this how-to, it was very helpful.

Hot tip if you lose your grip screws; they're exactly the same as the oval-head screws that hold the covers on household light switches and wall outlets.

I have a daisy 200 I was disassembling the gun the barrel from the casing and a spring fell out I reassembled it and I don't know where it goes please help

ReplyDeleteI have a daisy 200 and I was disassembling it pulling the barrel out of the casing toil everything in the spring fell out when I pulled the barrel out I don't know where it goes put the gun back together and now I have a spring out of the gun with the gun back together please help

ReplyDeleteReally easily done. Quite helping. Thanks for sharing.

ReplyDeleteA proper way of disassembly. Thanks, you have shared an important article.

ReplyDeleteHi I also have daisy 200, and like many other it leaks like crazy when I insert a CO2 cartridge... I took apart the gun completely. But I DJ t know what to fix to make it stop leaking... Could u tell somethings to do

ReplyDeleteMy 200 would shoot a few times, then you would hear air escaping from the rear quarter of the gun, and could not shoot any more, and the cartridge would empty.

ReplyDeleteMy first attempt: disassembled the gun per the OP's instructions, soaked everything in transmission sealer for a few days. Reassembled, putting teflon tape on the rear threads, and it worked, for about 6 cartridges, then it progressively worsened to just shooting 1 BB, and was back to the original bad behavior.

2nd attempt, same as before, but this time I noticed the o'ring on the rear assembly (beside the threads) was very hard. I took advice from above and bought an O-ring at the hardware store that fit: 3/8" i.d. 1/2" o.d. 1/16", slathered a bit of silicon grease on it, re-applied the teflon tape. So far so good! Will post again if it fails soon...

I post this because it 'seemed' like the leak was more forward in the assembly, in the area above the trigger. I never looked closely at the rear o'ring because it sounded like the leak was in a different area.

I'm still finding this page useful in 2022 lol. I fixed the leak at the piercing pin but I have a leak where the "piston" comes out of the back of the valve. The problem is the clear part of the three piece nested seals is mangled. Any thoughts on how to MacGyver something to work?

ReplyDeleteHi y'all, I just acquired, from what I've read, a later model CO200. the elevator spring went for a flight when I dis-assembled the gun. This one does not have the top pin hole for the elevator spring.

ReplyDeleteCan anyone tell me the spring wire diameter and free length? I've tried a few different replacements but just not the right pressure yet.

1 shot and the elevator sticks.

I also added a ball bearing to the top of the spring to aid in assembly and dis-assembly. This may be part of the problem...

The cartridge seal and pierce pin on this model sits in a cylinder that keeps the cartridge central to the pin. the seal in the bottom was dry rotted, so I made a seal from a thin piece of rubber by putting a 1/8" hole into a 5/16" outside diameter disc. the rubber is 1/16" thick, the 1/8" thick washer I made was too thick, the gun is sealed tight.

I just cleaned up my brother-in-law's 200 that had been hanging in his garage for 30+ years. It had mud dauber nests in the barrel, small spider skeletons in the shuttle, and patina galore. IT also had hand made grips that his brother made back in the day. The CO2 pin seals were petrified, so I removed those seals and the pin and replaced with a 200 piercing cup, with a new o-ring below it. The seals within the valve actually looked quite good, so I liberally applied Crosman Pellgun oil in the valve and a new o-ring at the valve head, and managed to shoot it a bunch of times. It does not always load bb correctly though, so maybe my technique is bad. The Crosman 454 is so far more reliable, but its trigger is awful and the Daisy is light and crisp.

ReplyDeleteWhat I can't figure out is how the valve is triggered, there is no hammer, and so far the elevator mechanism / CO2 release is a mystery...

Regards, wipemeout06@gmail.com