The valve uses the same piercing pin and seal as the 38T, 357, etc. This is good as I laid in a supply of them.

Big screwdriver unscrews the valve.

Not much to it.

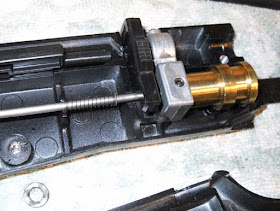

Here's what it should look like underneath the hammer.

An overview of the parts and their proper relationship.

The hammer cocked.

The rod transfers the hammer force to the valve stem. The plastic piece in between the valve and rod is the single shot pellet loading port. You have to half cock the gun, leaving the lever down, then pull the port up to load the pellet.

38A027, 38-128 seals. The design hans changed over time but they are interchangeable.

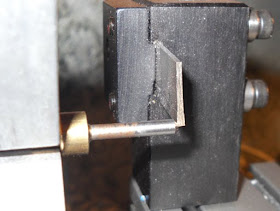

Setting the Taig lathe parting tool to the length of the old valve stem.

Parting off the new one (part #1322A011 from the 1377?) to length. The brass bit in the jacobs chuck is a piece of rod with a 60 degree cone in then end, it needs support as you have to use a bit of pressure to cut.. The stem is hard. It snapped at the parting line before I had a chance to remove the brass cup center to finish the cut. I then chamfered it with a file. In hindsight a cutoff disk would have done a fine job.

Old stem above, new one below.

A better shot of the safety.

If all the parts are in the right place you can massage it all back together no problem. You have to pull the hammer back a little bit to get it in. When putting the lever pivot screw in you have to pull the lever back a bit against the force of the springs.

Back together it's holding gas two days later. Not the highest power air rifle, but it promises 100 shots per cart with velocities between 500-300 fps, diminishing...which my Chrony confirms. It will shoot pellets as well, single shot. The rifle is a fun little can plinker. Because the bbs feed by gravity you have to angle the muzzle slightly downwards as you cock the rifle.

Hey Nick, where was the stuck pellet? BSH

ReplyDeletePellet fell underneath the single shot loading port, preventing it from being placed back down. Entirely my fault as I tried to push the stuck pellet into the loading port...but no harm done.

ReplyDeleteI have the same gun and when I screw in the co2 it just blows out at the valve. Could I need a new valve?

ReplyDeleteIt could just need a good valve cleaning, disassemble the valve and clean all the parts, then reassemble. If it still just blows out then you'll need a new exhaust valve. You should be able to buy a reseal kit from Bryan and Associates or other airgun seal suppliers.

ReplyDeleteNick:

ReplyDeleteMy 73 is blowing gas out of the pellet load port when fired. I was given the rifle and someone has cross threaded the barrel set screw. Know anyone that would have parts or interested in working on it? Matt

Parts try Bryan and associates. They will fix it as well. Tell them I sent you.

ReplyDeletehttp://www.bryanandac.com/

Nick

Hi, great help here. I took apart my old Model 73 I had when I was a kid and wanted to get it working for my son. I found out that the seals are shot and the guys you have listed dont want to deal with international orders that are new. Any where else I can go? Id hate to see this rifle sit, it brought much joy to me as a boy.

ReplyDeleteCheers!!

Scott,

ReplyDeleteIn the UK try: Lawrie Amatruda, lawrieandpat@talktalk.net

Nick