With the barrel pushed all the way in the breech there's a gap at the front. This is the same gap that I found inside the breech as the barrel was sliding back and forth.

I used loctite bearing retainer to seal the barrel in the breech. This will prevent any air leaks or movement.

I cut a metal washer.

Like so.

That takes up that space.

I found a sliding breech cover with appropriate "patina" on Ebay.

I made a new breech cover screw to fit.

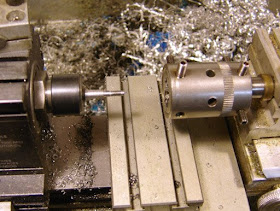

Slotting...

One of the sight holes went plumb through into the barrel...

So I wrapped a thin scrap of teflon tape around that sight screw. Should prevent air loss.

Finally, I found a knurled nut in my pile of parts I purchased last year.

Now the barrel doesn't move, air leaks are minimized and loading is much easier.

Nick, my 147BP only has a rubber flat washer as the air transfer port seal. No metal sleeve.

ReplyDeleteHi,

ReplyDeleteThanks for your brilliant guide on the Crosman 140. I had an old one which i managed to resurrect based on your documents. The parts I imported from Alan at www.Abairgun.com

The problem I have now is that after a few shots the pump washer seems to get locked inside and then ceases to pump and the handle becomes free.

I am not sure if this is due to heat caused by the Pump and wrong oil combination.

ANy ideas on that.

Thanks

John - India

You mean the pump cup comes off of the pump rod? Or that it caves in and won't push air into the valve?

ReplyDeleteCould be too much oil or oil that's too thick. Not really sure though. Might be a good idea to ask on the Green Crosman forum?

The pump cup comes off of the pump rod and the handle moves rather freely.

ReplyDeleteActually I haven't put much oil there at all. Maybe i should put a little Silicone oil there.

Let me check on the other forum as well.

Thanks Nick.

Silicone oil would be bad, use some thin motor oil but not a lot, just enough to moisten the felt wiper. Put some pics of the problem and parts up on the Vintage forum thread you started, it should be easy to diagnose.

ReplyDeleteI managed to fix the loose pump washer.

ReplyDeleteThe new problem here is that when i am pumping the gun, after the first pump the pumping lever just goes about 1/2 the way and then gets real tight and jammed there and refuses to go further up.

in other words when i try to pump im not able to extend the pumping lever completely to the end. as a result im not able to pump air into the chamber.

A sort of squeaking metallic noise comes before the jam, i dont see any bends / protruding metal parts - what could be wrong here.

Please help

John

Hi,

ReplyDeleteI managed to fix the problem to thought i would leave a note here so it might help someone with the same problem - first all the new washer was thicker than the original so i filed away one mm from it and then put it back in and sealed it well with some side punches - after that the metallic squeaking started again and that was fixed by a drop of oil.

the problem after that was the it would cock intermittently - sometimes after a few pumps and sometimes not even after 10 - that too was fixed by a drop of oil - so all is fine now and it works like a charm- the only thing is that the pump arm seems a little loose and hangs down - any ideas on that?