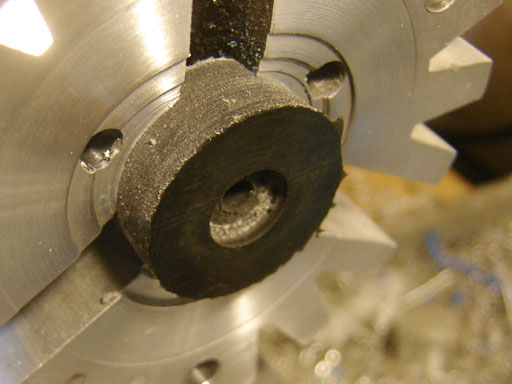

I chucked the plug up, drilled a hole through, then bored the recess.

I found this internal grooving tool in my drawer of misc. toolbits.

And I made the recess. The rubber didn't cut particularly well, but it did cut. If I had had some dry ice on hand I probably would have frozen the rubber first to make it easier to machine. But I didn't.

Hey, it snapped right on!

I mounted the plug on a mandrel and turned down the OD, finishing the last few thousandths with some 180 grit sandpaper.

I then parted it off to length.

I put the face groove in with an extremely sharp little tool I keep working on...

I then put the detent back in the barrel, and reassembled in reverse order. I lightly oiled the breech seal, which was somewhat rough.

I test fired the rifle. Before doing all the work it was shooting Crosman Premier Light pellets (7.9 grain) at 360 fps, although it was not a thorough test (I only shot a few through). After all this work it was spitting them out at an average of 312 fps. Not so good. I noticed that there was a light spray of oil on top of the breech. That hints at the fact that the breech seal may not be in the best shape.

So I found some leather and cut the OD for a new breech seal.

Then I carefully lined up a smaller punch for the OD. Then I made another one because the hole on the first one was off center.

I trimmed all the fuzz out of the center with an xacto knife.

The new seal in place, and oiled. I tested the rifle again and it was now shooting the CPL's at 394 fps. I was able to wring out better performance! Yay me!

I think I'll look for more Slavia airguns in the future. I have a 624 that was in very rough shape which I let the kids shoot, and the 631 I bought years ago at the flea market.

i have also an slavia 618 it is 30 years old and the striger doesent get stabilised so i cant load and shot.

ReplyDeleteEither the sear is worn or bent, hard to diagnose. See if the rod sticking out from the piston send with the notch is concentric or if it's bent and try and get it straight but it may just break off. Check for wear on the trigger sear notch. Good luck. Sometimes these old guns are just plain worn out.

ReplyDelete"end with the notch" not "send with the notch"

ReplyDeleteok i will try if it works i'll tel you

ReplyDeleteAbout 8 years ago I made a piston seal from heavy shoe soling leather soaked in melted mutton tallow. I made the seal slightly oversized and the first dozen or so firings were less than impressive but I recently got it out of the cabinet and put a pellet nearly all the way through a phone book. I don't recall it ever shooting this hard even when I was 10 years old. (I'm 40 now)

ReplyDeleteI have 618 rifle, and i need a stock for it. any suggestions on how to get one? And is it worth anything?

ReplyDeleteNot sure where you can get a stock, try JG airguns or Chambers gunmakers. They aren't worth that much though, maybe $100 in perfect condition and less for a well worn one.

ReplyDeletehttp://www.jgairguns.biz/

http://www.gunspares.co.uk/shopdisplaycategories.asp?id=23960&cat=Airgun+spares

hello,

ReplyDeleteI've also got a slavia 618 air rifle and i'm wondering how thick the leather for the front seal has to be.....

i used 1,75mm but i'm not sure, if that's enough....

(sorry about my bad english - i'm from germany...)

You just need to measure the depth of the recess for the seal and make the seal slightly thicker (it will compress, but it will also swell with oiling) The recess depth varies from gun to gun. If you made the seal too thin you can add thin shim washers underneath made from cardboard, plastic (from a yogurt container or soda bottle), thin aluminum or steel, etc.

ReplyDelete