First step was to press the pins out.

Then I took a picture.

I loaded the picture as a background into Rhino, scaled things by the distance between the two roll pin holes in the pump arm and did some design work.

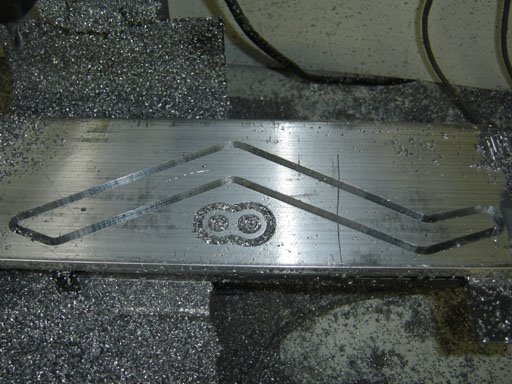

A 3/8" thick, 4" wide by 12" long give or take.

The two roll pin holes were spotted with an undersize drill bit.

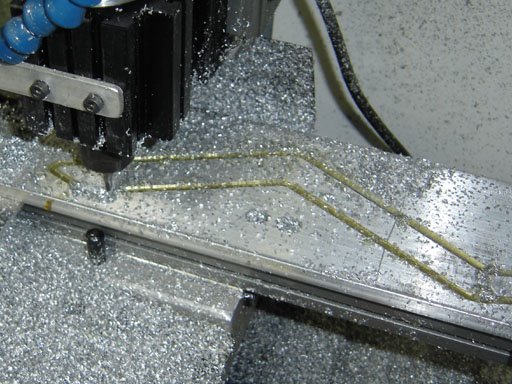

Then the mill did it's thing, helpful little robot that it is.

The cut progressed.

Hmmm, notice another barrel band there? Turns out the first one I did had the holes a bit too far apart, which I only noticed when I removed the pump arm.

Rather than let things just drop out of the plate, I programmed it to leave .050" thick "sprues" on the parts connecting them to the plate.

This is a really great, and lazy way to fixture things.

The pieces were separated from the plate with the band saw.

I probably should have nested some other parts in there, that scrap will be hard to use...

The little sprue ends will be sanded off.

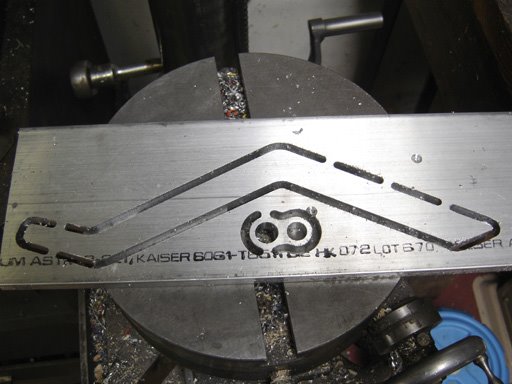

Reaming the roll pin holes after drilling through.

I spent about 30 minutes figuring out how to fixture the pump arm so it wouldn't hit anything as the table travelled. I then used the indicator to make sure the top was parallel to the table.

I milled the top flat, getting rid of 3 of the "sprues" Notice the Kant Twist clamps, you can never clamp a part too solidly in a setup like that.

The channel was milled for the pump linkage.

Pinned to the 1377. I'm not sure if I'll stick with the roll pins, or use screws, or what.

You get a heck of a lot more leverage with the longer arm.

This is the mess I created. Several dustpans of chips were removed from the manual and CNC Taig mills.

With that patent is it easier to pump the gun? because with the stoch plastic is hard for me.

ReplyDeleteIt's easier as you have more leverage. I got the idea from match pneumatic pistols as well as a picture on the russian airgun forum showing a rod welded to the steel pump arm to achieve the same leverage.

ReplyDeleteThanks for the reply my friend.

ReplyDeleteYou have done nice work. You have the right tools for this work.

I wonder how can i make one for my gun. I dont have these tools.

Can you give some dimensions for that?

What material is this?

Do you thing that a wooden one is weak? sorry for my english.

I don't have a useful drawing of it. It's aluminum. You could make one of wood but it would have to be a strong wood and be somewhat thicker.

ReplyDeleteBest thing would be to take the pistol and a picture and find a machine shop or metal craftsman who could duplicate it.

I'm a latecomer tot his posting but I just found a pic of the gun and had to figure out what you did to make the pump arm.

ReplyDeleteVery nice.

I'd think that many might be willing to pay handsomely for one of these. The combo leverage and rest is a winner.

Thanks Mark! I'm trying to keep this a hobby as making stuff for people is never as much fun as it sounds. Still it's on my back-burner list if I ever need to.

ReplyDeleteNick

That pump handle is genius! It would really make it more pleasant to pump up the gun. I think you could make and sell these, $40 easily, even if it was in the white (bare metal) I'd buy one in a hot minute if you even make these anymore).

ReplyDeleteHe made an excellent pump arm. But that shape seems like a bow saw frame. We might cut / modify a bow saw frame into that pump arm.

ReplyDelete