"One part of three all done. Part 2 to follow in a bit..."

There are three parts to the assembly, but only two parts to my blog post about making it! So here's how the other two parts of the assembly were made.

The plug completed, I then did a little programming and made the barrel band on the Taig CNC mill.

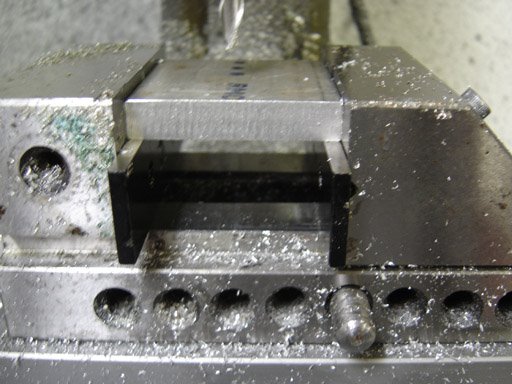

A piece of 3/8" thick aluminum mounted in the vise.

Notice it's supported on parallels well away from the center of the piece.

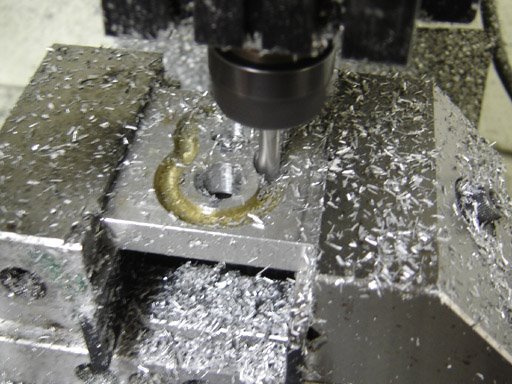

Interpolating the barrel and plug holes with an end mill. While not as good as drilling and boring, it's close enough.

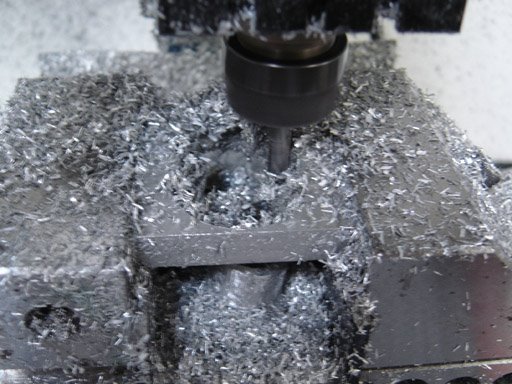

Staring the contour cut.

I took several passes around.

In the end, the part dropped free.

A bit of filing, sanding and general deburring and the part is done.

I assembled the band on the plug and barrel.

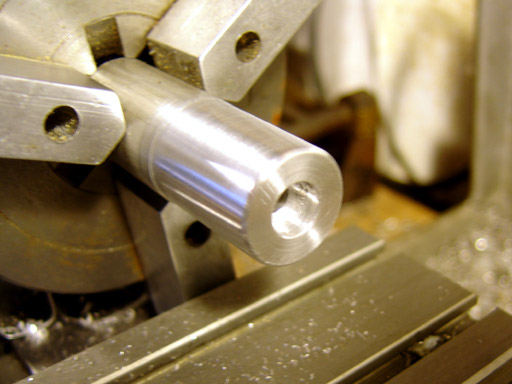

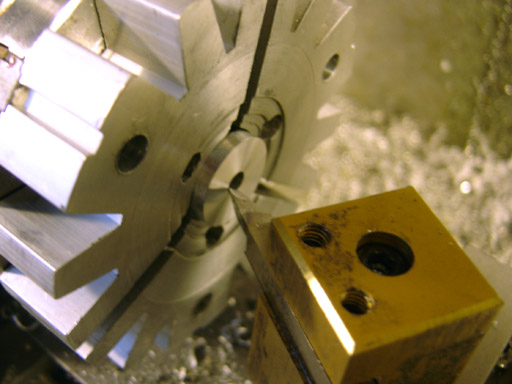

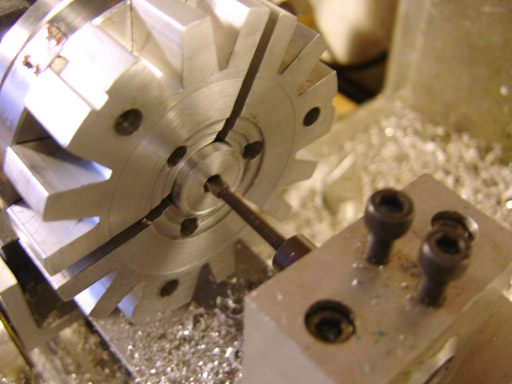

Drilling for the end cap.

Counterbore for #10 screw.

The screw will sit flush with the end of the cap.

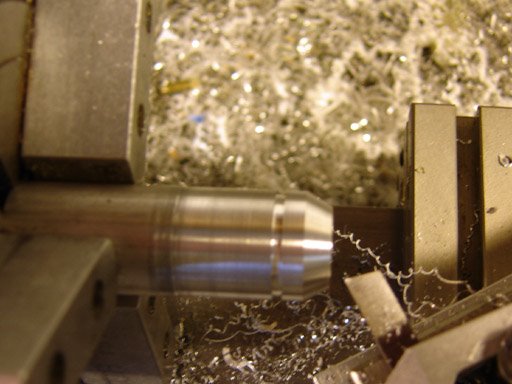

Cutting off to length.

Wait! I decided to angle the end first. Just to make it pretty.

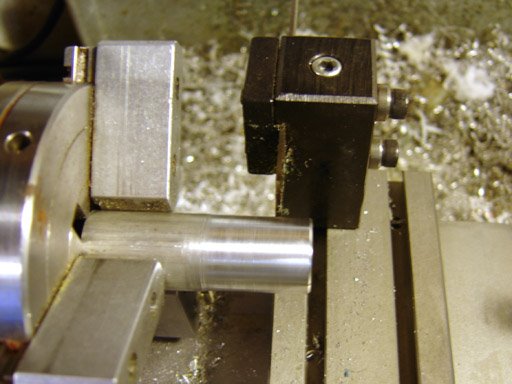

You'll notice the weird way the tool is clamped to the top slide. Well a customer had an emergency and needed to replace the toolbit clamp for his top slide. So I sent him mine and forgot to order a replacement one from Taig...thus this kludge.

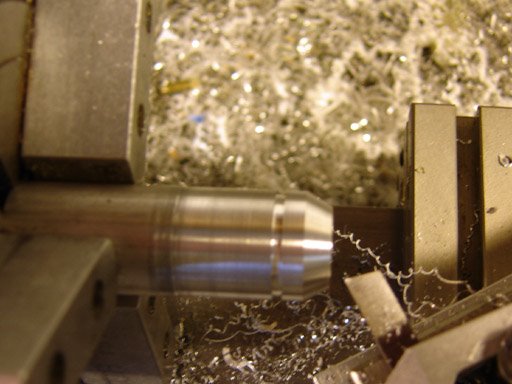

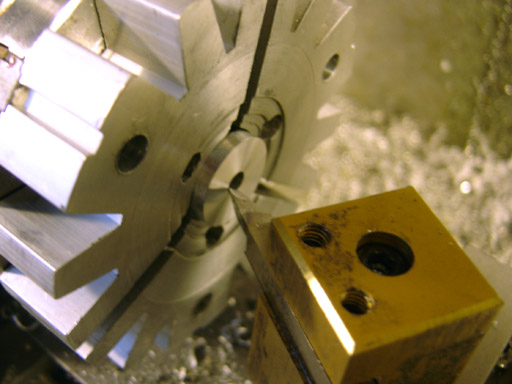

Turning the taper. Notice the groove from starting to part off and then reconsidering. This is not a planned, rather an evolving, project.

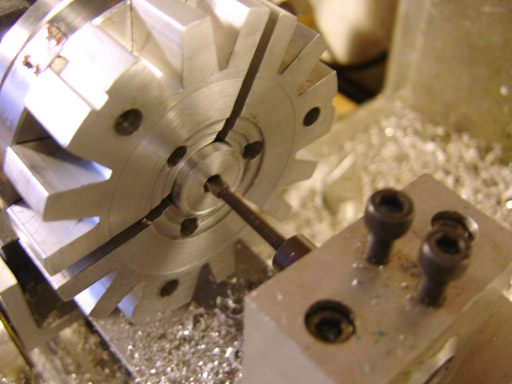

Then I parted it off, and flipped the part around and mounted it in the full circle jaws on the 3 jaw chuck. I then faced it flat as parting often isn't perfect due to flex in the blade.

I bored a slight relief on the face.

All done!

I assembled everything. It pleases me, and is a start to the sci-fi look I think the gun will end up with.

One assembly done, how many more to go?

Turning the taper. Notice the groove from starting to part off and then reconsidering. This is not a planned, rather an evolving, project.

Then I parted it off, and flipped the part around and mounted it in the full circle jaws on the 3 jaw chuck. I then faced it flat as parting often isn't perfect due to flex in the blade.

I bored a slight relief on the face.

All done!

I assembled everything. It pleases me, and is a start to the sci-fi look I think the gun will end up with.

One assembly done, how many more to go?

Well, so that's how you use those shiny machine tools! Nick, you've got to start making some small batch runs to sell these to the guys on the Crosman forum. I think you'd get bored making them all the same, though. You did take the time to write the program code for the CNC, so why not? If nothing else, use any $$$ made for airguns to mod to feed more blogs.

ReplyDeleteDerrick